During the construction of the sewer system in a private house or in the country, accumulative wells are necessarily erected. Regardless of the type of structure, they must be cleaned. If you know how to do this correctly, problems with the use of sewage lines will not appear.

Well cleaning intervals

When sewage flows into the well, heavy particles settle to the bottom in the form of sludge, and clarified water remains on the surface. Gradually, an increase in silt mass occurs, which leads to a decrease in the throughput of the treatment plant, hindering the effective operation of the sewage system. If the contents of the well are too silted, harmful bacteria actively develop in it, which, when they penetrate the earth, adversely affect the environment and the health of the residents of the house.

The frequency of cleaning activities depends on the operational characteristics of the structure:

- volume;

- configurations;

- the presence of filtration plants.

Usually the procedure is carried out once a year, but sometimes this period increases to three years, and in some cases it is necessary to call specialists once every three months.

Cleaning of sewer wells is planned and emergency. The first method is carried out after filling the tank with wastewater three quarters of the volume. The second is performed with a sharp decrease in the performance of the treatment plant, as a result of which the functioning of the entire treatment system is disrupted.

Neglecting the implementation of planned activities and calling up trash cans, when the treatment plant can no longer process waste water, leads to rapid deterioration of the system. Its repair is expensive. In order to prevent an emergency, cleaning should be done on time.

Basic cleaning methods

Three methods are most often used for pumping wastewater from sewage treatment plants and pipe cleaning. Each of them has its own advantages.

Use of a suction pump

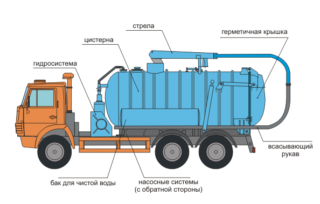

Special equipment, consisting of a tank and a vacuum pump, is used to carry out sewage works. The advantage of the technology is that a similar procedure can be carried out at any time of the year. The budget cost is also important. Sludge pumps are used to remove the silt layer in wells, septic tanks and highways made of plastic and concrete. After cleaning, liquid waste is transported for further disposal. Scheduled pumping of sewer wells is usually carried out in this way.

Vacuum method

It includes such types of manipulations as cleaning the sewage system and pumping out dirty drains with a high-capacity vacuum pumping device. The pump is able to remove suspensions with fractions of any size. The mixture is pumped into a special tank, and then transported to a treatment plant. It differs from the previous method in productivity due to the use of more modern technology.

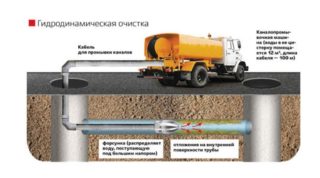

Hydrodynamic method

Cleaning is carried out using a device that produces a water stream under high pressure. It cleans any deposits from the walls and bottom of the device. The washing device can be autonomous or mounted on the platform of a special machine.

Cleaning is carried out using a device that produces a water stream under high pressure. It cleans any deposits from the walls and bottom of the device. The washing device can be autonomous or mounted on the platform of a special machine.

The methodology is safe for the environment and human health, the cost of such a service is available to the owners of personal plots.

The advantage is that the flow of water under pressure rinses off almost all organic and inorganic deposits on the walls and bottom of the well.Hydrodynamic cleaning is used not only for well reservoirs, but also for clogged pipe lines.

If siltation and pollution are strong, it is recommended to combine this technique with pumping out with a vacuum pump.

Assistive Techniques

To clean wells with persistent dirt, additional methods are used:

- heat treatment;

- use of chemicals;

- manual cleaning.

The first method is similar to cleaning using hydrodynamics, but the water flow supplied under pressure is heated to 120–160 degrees. Hot water better removes hardened deposits and layers of fat. The method is used only in difficult cases, since it is technologically difficult to implement.

When treated with chemicals, mud and grease are destroyed at the molecular level. Chemicals are foamed. This makes it possible to clean the bottom and vertical surfaces of the sewer tank. The chemical method is effective and does not harm the environment and human health, but is rarely used due to the high cost of cleaning substances.

The manual method allows for the complete elimination of any formations. Purification is carried out manually after pumping out the drains, when no more than a cubic meter of sediment remains on the well bottom. The layers are brushed off with a spatula and removed from the tank using a conventional bucket.

Toxic volatile substances are formed in sewer sumps. When manual cleaning in the well, you must carefully follow the safety rules and put on specialized equipment: protective masks, gloves. At least two people must insure a worker on the surface.

Reducing the frequency of cleaning activities

Any method of cleaning sewer wells will require investment of money, time and labor. To save money, it is necessary to make so that cleaning procedures are required as little as possible.

Any method of cleaning sewer wells will require investment of money, time and labor. To save money, it is necessary to make so that cleaning procedures are required as little as possible.

Ways to reduce the frequency of cleaning while maintaining the operational characteristics of the sewer well:

- Increase tank volume. Its calculation is initially carried out based on the number of residents of the house. If the number of residents has increased, the well will fill up faster, it will have to be cleaned more often. To avoid this, you can add volume to the structure by attaching an additional chamber using an overflow pipe.

- Use active sludge mass. The complex of beneficial bacteria absorbs pathogens and accelerates the decay of organics in sewage. They feed on organic suspensions in sewage, making the fluid much cleaner.

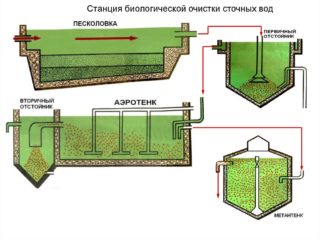

- Purchase a bioremediation station. The most expensive option, but over time it pays off. Installation differs from a simple well tank in that wastewater can be cleaned up to 95 percent. As a result of the activity of cleaning bacteria and the operation of a complex filtration system, almost all harmful suspensions are removed from the water, so the processed liquid can be used for irrigation.

If there is small deposits in the sewer line, it is enough to rinse it with running water. The manhole of the inspection well is closed with a stopper, and a stream of water is passed under low pressure along the highway. Then the cork is removed, water at high speed goes into the well tank and flushes it

The choice of cleaning method depends on the degree and type of contamination. Usually one or two standard processing methods are sufficient. Modern wastewater special equipment is equipped with all the necessary equipment.

If the network requires major cleaning, it will be necessary to process not only the well, but also the pipeline itself. In this case, heat treatment and washing with chemicals are additionally used.