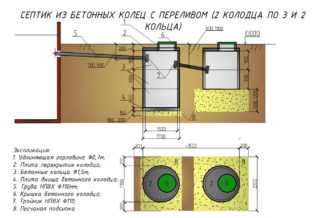

Reinforced concrete rings are a popular building material that is often used in the construction of autonomous sewer systems. Wells are collected from them, where drains are drained, where the latter are partially processed. Rings are made by injection molding. As a starting material, a concrete solution is used. Previously, a reinforcing frame of steel reinforcement is laid in the molds, which is assembled in the form of a lattice.

Types of Concrete Rings

Manufacturers offer an expanded range of concrete products. Two or three decades ago, this material was presented in a single copy - solid rings with flat ends. Their installation was carried out using a cement-sand mixture, which was used as a masonry mortar. They fastened the elements together with metal brackets.

Manufacturers offer an expanded range of concrete products. Two or three decades ago, this material was presented in a single copy - solid rings with flat ends. Their installation was carried out using a cement-sand mixture, which was used as a masonry mortar. They fastened the elements together with metal brackets.

Today on the market you can buy rings of a different design:

- With lock (seam) connection. The upper end is a fold with an internal recess, the lower - with the outer. When installed on top of each other, there is a close fit of the fold. To increase the tightness of the junction, a sealant is placed between them in the form of a rubber band or a foamed polymer.

- Filtrational. Concrete rings, along the entire plane of which perforation is made in the form of through holes. Such products are used to form filtration wells into which clarified (purified) water flows. It passes through holes, penetrating the ground.

- Extra. These are non-standard height sewer rings that are used if standard rings are not enough to provide the required height of the well. They are presented on the market with flat and seam ends.

Manufacturers of reinforced concrete products offer additional elements to the rings: bottoms for wells and covers with openings for manholes and ventilation pipes. Both elements are produced in accordance with the diameters of reinforced concrete rings.

All sewer rings and additional elements are standardly labeled:

All sewer rings and additional elements are standardly labeled:

- KS - wall ring;

- PD or PN - bottom plate;

- PP or PC - floor slab.

In addition to the letter designation, there are also numbers in the marking. For example, COP 10-9:

- "10" is the internal diameter in decimeters, that is, it is 1 m;

- "9" is the height of the product (dm), that is, 90 cm or 0.9 m.

Manufacturers add another literal meaning to the labeling. It denotes the permeability of concrete. Normal permeability is designated - N, low - P, especially low - O.

In addition to this kind of marking, there is a classification that divides the concrete rings according to their purpose. Accordingly, their letter designations are different. The KS brand is usually used for the construction of small-sized wells. Therefore, they are used in the construction of domestic sewer structures.

Other brands:

- KO - the ring used as the supporting part of the well structure is laid in the lower part of the assembly;

- KVG - can be used for the construction of wells intended for the installation of gas or water pipes.

- KLK are used for the construction of wells for storm sewers being built inside the city;

- CPK is used to form the collector network.

All types of concrete rings differ from each other by the brand of concrete solution, as well as by the degree of permeability of the source material. Products "KVG" are not exposed to moisture loads during operation. They are made of concrete with a particularly low permeability, which reduces the price of the product.

Manufacturers offer rings with a bottom. Elements of this type are labeled as “DK”. When creating a sealed well structure, such products are laid at the very bottom.There is no need to lay the bottom and seal the joint between it and the lower ring.

Standard sizes

Three dimensional parameters are standardized in concrete rings: inner diameter, height and wall thickness. The table shows these parameters, plus the weight of the products.

| Name | Dimensional parameters, mm | Weight kg | ||

| diameter | height | wall thickness | ||

| COP 7-1 | 700 | 100 | 80 | 46 |

| COP 7-1.5 | 700 | 150 | 80 | 68 |

| KS 7-3.5 | 700 | 350 | 80 | 140 |

| COP 7-5 | 700 | 500 | 80 | 230 |

| COP 7-6 | 700 | 600 | 80 | 275 |

| COP 7-9 | 700 | 900 | 80 | 410 |

| COP 7-10 | 700 | 1000 | 80 | 457 |

| COP 10-5 | 1000 | 500 | 80 | 320 |

| COP 10-6 | 1000 | 600 | 80 | 340 |

| COP 10-9 | 1000 | 900 | 80 | 640 |

| COP 12-10 | 1200 | 1000 | 80 | 1050 |

| COP 15-6 | 1500 | 600 | 90 | 900 |

| COP 15-9 | 1500 | 900 | 90 | 1350 |

| KS 20-6 | 2000 | 600 | 100 | 1550 |

| KS 20-9 | 2000 | 900 | 100 | 2300 |

If the last digit in the marking of concrete products is not worth it, the default height is 90 cm. All other height values are required.

Concrete Ring Volume

To the volume of the rings of the sewer wells fit, as to the calculation of the volume of the cylinder - by multiplying the height of the product by the cross-sectional area. The last indicator is calculated by the formula:

S = πD² / 4 = 3.14D² / 4.

For example, for a ring of the brand KS 10-9, where the diameter is 1 m, the height is 0.9 m:

S = 3,14х1² / 4 = 0,785 m² - this is the cross-sectional area.

V = SxH, where H is the height of the ring. It turns out: V = 0.785x0.9 = 0.7 m³ - this is the volume of the ring of the brand KS 10-9.

How to correctly calculate the required number of rings

The sewer system is calculated taking into account drains that merge into a precast concrete well. The more there are, the more capacity should be. To calculate, you need three parameters:

The sewer system is calculated taking into account drains that merge into a precast concrete well. The more there are, the more capacity should be. To calculate, you need three parameters:

- the number of people permanently living in the house;

- daily rate, which falls on one person - this indicator is standard, in SNiPs and SanPiNahs 200 liters per day or 0.2 m³ / day are indicated .;

- the time during which bacteria process organics - this indicator is also standard - 3 days.

The indicated values must be multiplied among themselves. The final indicator is the required volume of the sewer well. For example, if 3 people are constantly living in the house:

V = 3х0,2х3 = 1,8 m³.

To get such a volume of a concrete tank, it is necessary to divide the obtained value into the volume of one ring. For example, with the same brand of COP 10-9:

1.8: 0.7 = 2.57, rounded up, it turns out - 3 rings.

It is necessary to take into account the moment that the sewer pipe is introduced into the well at a certain distance from the upper end of the upper element. This indicator should not be less than 30 cm. And this volume will need to be taken into account when calculating the number of concrete products.

In some regions, it is problematic to make large indentations. This is prevented by permafrost or high groundwater levels. In this case, they try to install reinforced concrete rings of a larger diameter.

For example, if KS 20-9 rings are selected, the volume of one element is 2.8 m³. That is, for a house where 3 people live, one ring is more than enough. You do not need to dig a deep foundation pit under it, it deepens to a maximum of 70-80 cm. This simplifies construction work and reduces the budget. Therefore, it is very important to first carry out all calculations, and then move on to construction work and the acquisition of materials.