Pipes for utility networks are selected depending on the location and purpose of the pipeline, the volume of circulating water or wastewater. The main parameters are diameter, thickness and material. The most popular polymer products. For laying the outside (street) part of the collector, use a red sewer pipe with a diameter of 110 mm in private households and 200-300 mm in public networks.

The use of pipes with a diameter of 300 mm and manufacturing materials

Products with a large cross-section are intended for laying the outer part of engineering networks: public sewer highways, underground stormwater or cable channels. Inside buildings, such tubes are not used.

There are several types of sewer pipes on the market, which are divided according to the material of manufacture. Rating as the popularity of the product increases:

- Reinforced concrete. Such tubes are gradually becoming a thing of the past and are being used less and less. The main prerequisite for this is too much weight, requiring special equipment for laying the trunk and the relative fragility of the material. With a strong point impact, the pipe may burst. With careful installation, the reinforced concrete collector lasts up to 70 years. But at the same time, its walls have a relative roughness, so the collector silts with time. Reinforced concrete is resistant to temperature changes and is inert to aggressive impurities in the effluent, it can withstand pressure from the soil.

- Cast iron. Strong, durable material. It has a lot of weight, which is not always convenient. For transportation and laying of a metal collector, you will need to hire special equipment. Cast iron service life is 50 years or more. Metal is prone to corrosion. More often cast-iron pipes are used when laying complex pipelines. In private construction, such products are not used.

- Asbestos cement. A relatively new, updated version of reinforced concrete pipes. In their manufacture, the cement solution is mixed with polymers, which act as reinforcement. The result is a strong, durable and at the same time lightweight material with perfectly smooth inner walls. Asbestos-cement pipes are able to withstand heavy loads, both static and dynamic. Laying can be done in 4 hands.

- Polyethylene. Tubes are good for laying underground utilities. PET is prone to linear stretching, inert to temperature extremes and aggressive environments. The inner walls are perfectly smooth, which allows the use of polyethylene products for pressure-free networks. Serve from 50 years, while being easy to install.

- Polyvinyl chloride. For laying the outer parts of the collector, only pipes painted in orange are used. Gray ones are intended for indoor use. A red hue indicates that the material responds well to temperature changes and has high strength to static, dynamic loads. For greater resistance to soil pressure, PVC tubes are placed in a special corrugation. Rings play here the role of stiffeners. As a result, corrugated products withstand pressure up to 120 atm. Red pipes are inert to aggressive environments, calmly and without pressure transport large volumes of effluents due to smooth internal walls.

- Asbestos cement

- Concrete goods

- Cast iron

In order for tubes with a section of 300 mm to calmly withstand the pressure of the soil, their walls are made from 16 to 29 mm thick. When buying, you need to pay attention to the indicator of the inner diameter. Products are produced with or without bells.

Principles of installation of a pipeline with a large cross-section

Depending on the material of manufacture, sewer pipes with a cross section of 300 mm are connected in different ways.

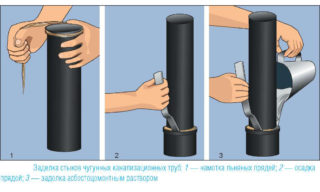

Reinforced concrete and cast-iron products are joined together in a bell using a special solution. For its preparation, cement, water, glue are combined in a ratio of 2: 1: 1. The mass is well kneaded until smooth. Lay the first tube with a bell to the next. Next segment of the collector is driven into it with a narrow end. The gap between the cuff of the bell and inserted into it a segment of the next element caulk. To do this, use an old rag, tow, torn pieces of paper. The prepared solution is applied on top and allowed to dry completely.

Asbestos-cement pipes can be connected in different ways. If a double-breasted coupling is used to connect two tubes, the stages of work look like this:

- A coupling is put on the junction of the two elements, after having previously inserted a sealing ring into it. In this case, the fitting should be located strictly perpendicular to the axis of the collector.

- Clean the surface of two tubes at the docking site from dust and dirt.

- The next element is brought to the previous one and with the help of a jack, the clutch is first moved away from itself, and then to itself. As a result, the fitting, as it were, immediately covers two parts of the pipeline.

If the master decided to use a PET coupling, the joining of two asbestos-cement products takes place in the following sequence:

- Two elements are laid in a previously prepared trench.

- A clutch is heated in hot water (approximately 90 degrees), the cross section of which is still several mm smaller than the outer diameter of the tubes.

- The fitting that has become elastic is put on the pipes with force so that both ends abut against the inner ring stop.

With the help of a cast-iron fitting, asbestos-cement tubes are joined as follows:

With the help of a cast-iron fitting, asbestos-cement tubes are joined as follows:

- Two parts of the future collector are brought closer to each other.

- The joined sides of the tubes are cleaned of dirt and dust.

- Mounting sleeves and flanges are put on the ends of the products.

- Two pieces of tubes are compressed as much as possible, and the coupling is pulled together by fixing bolts.

When using a cast-iron fitting, it is possible to assemble a split collector. If necessary, it will be possible to replace one of the sections of the highway.

PVC pipes with a diameter of 300 mm for external sewage are mounted in a bell. Use a special rubber seal, usually it is already included. If it is not there, you have to buy it on purpose. When installing the polyvinyl chloride collector, the ring is inserted into the socket of the tube first. The narrow edge of the next element is lightly treated with emery so that the adhesion of the sealant with it is better. A thin layer of silicone is applied to the prepared edge, wait 30-40 seconds and drive the tube into the socket until it stops. The whole network will dry for about a day. After that, the collector can be checked for leaks and backfilled.

It is better not to compact the soil above the polymer pipeline. Over time, he himself will shrink and will only have to pour the earth into place.

The cost of pipes is 300 mm

Prices per meter of plastic sewer pipe with a diameter of 300 mm vary depending on the manufacturer and the composition of the polymer. High-quality material on average costs 1000-2000 rubles. Cast iron products are many times more expensive.

For mounting a private collector, it is better to use corrugated products. They can also be used as wells for laying underground stormwater.