A PVC pipe with a diameter of 200 mm is used to create an external sewage system. Products of this diameter are painted in red color, since they are mounted only outside the building and go deep into the ground. Orange pipes are clearly visible on dark soil. They are able to withstand low temperatures and high ground pressure.

Advantages and disadvantages of 200 mm pipes

Pipe lengths with a cross section of 200 mm are one of the most durable plastic systems. Their main advantages:

- Rigid walls of the pipeline, allowing to keep a lot of pressure both outside and inside.

- Long life due to rust immunity.

- Easy to install due to the light weight of the structure.

- Resistance to temperature differences.

- Resistance to aggressive chemicals.

- Insignificant coefficient of linear expansion, which contributes to maintaining the integrity of the pipeline even during freezing.

Pipes with a cross section of 200 mm withstand a large thickness of the soil layer, so they are used to equip the external sewage system in harsh climatic conditions. The pipeline can be laid to a depth greater than the level of freezing.

Due to the high smoothness of the walls, contaminants do not stick to the inner surface of the pipe. As a result, there is no need for additional work to clean the line, which reduces operating costs. Prices for plastic sewer pipes made of PVC with a diameter of 200 mm starts at 500 rubles per linear meter.

The matrix matrix of the pipe is usually unplasticized polyvinyl chloride (NPVC) - a polymer obtained from vinyl chloride that does not contain plasticizers. The material has the following qualities:

- fire resistance;

- resistance to frost;

- low melting point.

He is a dielectric, not combustible, hard enough.

Nevertheless, pipe sections for PVC sewage are subject to deformation if the temperature of sewage rises to 70 degrees Celsius. They also collapse under the influence of organic solvents, if they are poured into the sewer. With strong mechanical stress or kink, the pipe may break due to slight elasticity.

If such risks are expected, it is better to install external pipes made of polypropylene or polyethylene. The former are able to withstand the effects of higher temperatures. Pipelines made of polyethylene do not freeze, they are flexible and durable. They easily restore their shape in case of small deformations. The cost of 200 millimeters made of polypropylene or polyethylene is higher. In the first case, it starts at 600 rubles per linear meter, in the second - from 900 rubles.

Corrugated pipes with a smooth inner surface and an outer dense shell are distinguished by enhanced characteristics of strength and flexibility. Such products with a cross section of 200 mm are made of different types of plastic. The price of PVC corrugated pipe is higher than usual. For example, Korsis double-layer corrugated products of this diameter cost 926 rubles per linear meter.

Specifications

Pipe sections with a diameter of 200 mm, used in external sewers, are produced by the method of three-layer coextrusion of polyvinyl chloride. They are made with a wall having an internal foam layer.

When choosing a pipeline, the index of ring stiffness is taken into account - the highest load value at which the vertical section deviates by a maximum of four percent. Side rebound is not taken into account.

The rigidity class of 200 mm pipes is SN 4. If necessary, it is possible to use pipe segments of class SN 2, SN 8. The standard length is 7 or 8 m.

According to the method of use, the sleeves are divided into pressure and non-pressure. The first type is used in sewage systems under pressure, that is, with forced movement of wastewater. The second is chosen for gravity-type networks.

The requirements for pipe products for an external sewage system depend on the configuration of the pipeline, as well as the type and volume of wastewater. The main indicators that are taken into account when choosing pipes are:

- resistance to static and dynamic influence;

- resistance to deformation under the weight of the soil over the pipeline;

- lack of displacement at the connecting sections leading to depressurization due to groundwater movement;

- resistance to damage from the loads of passing vehicles and pedestrians.

The wall thickness is developed and selected in accordance with the cross section of the pipe. This indicator affects the permissible depth of the pipe sections.

For a channel with a cross section of 200 mm with a wall thickness of 3.9 mm, the maximum laying depth is four meters. Pipes with walls from 4.9 mm can be buried by 6 m, more than 5.9 mm - by 8 m.

Mounting Features

The installation of an external sewage line is completed by such structures as a local treatment station or a cesspool with overflow, and begins from the point of withdrawal of the pipe system outside the building.

The installation of an external sewage line is completed by such structures as a local treatment station or a cesspool with overflow, and begins from the point of withdrawal of the pipe system outside the building.

When installing the pipeline in advance, make a plan indicating the location of structural elements on the site. Consider the minimum distance from the house to the VOC - 50 m. Decide on the location of the septic tank, cesspool, drainage well. Purchase the necessary materials taking into account the cross-section of the nozzles.

Steps for installing a 200 mm pipeline:

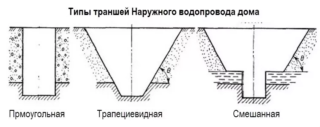

- In accordance with a pre-compiled plan, dig the desired number of ditches, the width of which exceeds the cross-section of the nozzles.

- Create a sand and gravel cushion at the bottom of the trench, and then lay a layer of geotextile.

- Connect the pipe segments and lay the pipeline in a trench. Minimizing the turning and winding sections of the highway will increase the tightness and reduce the risk of accumulation of deposits. During installation, fitting elements from a material similar to the connected segments are used.

Bury the trench in the reverse order. We should not forget about the arrangement of inspection wells at turning points of the direction of the highway, significant differences in height. They are also equipped on flat areas - every 6–12 m. After hydraulic tests have been carried out, it is possible to warm the sewage system.

Pipe connection

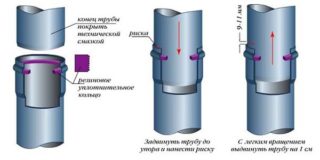

When installing plumbing and sewer plastic pipelines, pipe sections are usually connected in a bell-shaped manner. The purchase of products with bells greatly simplifies installation. The network is routed due to the fact that the smooth ends of the others are inserted into the sockets of some pipes. Improving the waterproof properties is due to the rubber sealing elements. Often they are already structurally provided in bell-shaped products.

If the pipe is produced without a seal, the best option for protecting the joint is to use plumbing sealant. It is applied evenly to the smooth end of the pipe section. The quality of the connection can be improved by pre-processing the articulated areas with sandpaper.

After applying the sealing compound, the end of the pipe is inserted into the socket of the other until it stops, then it is pushed back 10-15 millimeters, pressed.The presence of a gap prevents the deformation of the pipeline at temperature extremes.

After installation is complete, it is necessary that the pipe end enters the socket by at least four centimeters. Eliminate the possibility of a highway accident and protect it from freezing allows the installation of thermal insulation. Installation of insulation materials and a heating cable is carried out only after hydraulic tests - a ten-minute injection of water flow into pipes.

The red plastic sewer pipe is used in household sewage networks of buildings for various purposes. In addition, it is great for plumbing, drainage and storm systems. For high-quality operation, compliance with the assembly technology at all stages and the mandatory conduct of hydraulic tests to check the tightness of the joints of the trunk are required. All this will ensure a long service life of the sewer network.