High-quality clarification of effluents guarantees complete safety for the environment when discharged into water bodies. The sewage treatment process proceeds in several stages. One of them is the use of flocculants for wastewater treatment. Thanks to the chemical reaction, all micro- and macro-suspensions in the composition of sewage become larger. This allows you to remove them later in a mechanical way.

Definition and purpose

Flocculants are called chemicals that contribute to the purification of domestic and industrial wastewater from impurities. As a result of the reaction, all third-party substances in the dirty liquid form into flakes. Flocculation is used as a secondary stage of purification after coagulation. The main purpose of the reagents:

Flocculants are called chemicals that contribute to the purification of domestic and industrial wastewater from impurities. As a result of the reaction, all third-party substances in the dirty liquid form into flakes. Flocculation is used as a secondary stage of purification after coagulation. The main purpose of the reagents:

- preliminary purification of water from reservoirs before its supply to city communications;

- clarification of industrial effluents from dairies, chemical / pharmaceutical enterprises, etc .;

- domestic wastewater treatment.

Flocculation is also an integral part of such processes as the production of drugs, enrichment, and refining of petroleum products.

Types and classes of flocculants

All reagents for flocculation are divided into classes according to the type of their origin:

- Organic (natural): guar gums, starch and dextrin, sodium alginate, cellulose ether.

- Inorganic: silicic acid. It is especially active against metal hydroxides - aluminum, iron, magnesium, etc. As a result of the work of silicic acid, heavy, durable flakes are formed.

- Synthetic: high molecular weight compounds that are organically soluble in water and their molecular weight varies from thousands to millions.

There are also cationic, anionic and neutral flocculants (in terms of electric charge). The most popular is the latter type - polyacrylamide (PAA). Aggregate state of the reagents: liquid and powder.

The principle of operation of flocculants in water

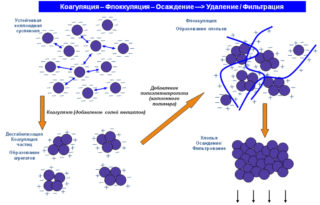

When reagents are added to contaminated water, the following process occurs:

When reagents are added to contaminated water, the following process occurs:

- All flocculants interact with colloidal particles. First settle on their surface, significantly disrupting the water-salt balance of the shell. In parallel, flocculants negate the electric charge of colloidal impurities. Initially, all colloidal compounds are surrounded by a shell that interferes with the adhesion of particles. It is destroyed by the flocculant.

- Due to its high molecular weight and the reactions that have already taken place in the water, the reactants are fixed on the surface of external impurities. Moreover, they form a kind of bridges, due to which a bond is formed between the flocculant molecules.

- As a result, all suspended particles of colloidal solutions coalesce into large visible flakes. They are also called flocculi.

After the reaction, extraneous impurities in the form of flakes can be easily removed from the clarified liquid. This is done using mechanical filters.

The effectiveness of the chemical method

Flocculation as a way of wastewater treatment allows to cope with large volumes of contaminated liquids with high efficiency. At the same time, we can safely speak of a high intensity of the clarification process with minimal costs. As a result of using flocculants, one can achieve the following results:

Flocculation as a way of wastewater treatment allows to cope with large volumes of contaminated liquids with high efficiency. At the same time, we can safely speak of a high intensity of the clarification process with minimal costs. As a result of using flocculants, one can achieve the following results:

- to clean the most polluted domestic / industrial wastewater;

- seriously accelerate the process of deposition of impurities in the liquid;

- to prevent the possible ingress of contaminants into the water in the next stages of treatment;

- abandon the additional costs of enhancing the performance of the treatment plant;

- extend the life of mechanical filters on VOCs;

- reduce the cost of capital clarification of effluents.

All the effects of the use of flocculants can be discussed only if the method is used in combination, after the coagulation stage. As a rule, the reagents themselves do not purify water fully, the method does not work.

The inclusion of the flocculation process in the wastewater treatment system is especially important if the station will soon receive large volumes of contaminated water. Here, without a thorough modernization of VOCs and significant financial investments, it will be possible to maintain the performance of the treatment plant. In fact, you have to spend only on the purchase of flocculant powder.

Using the above method in everyday life is irrelevant, since the process is complex and unjustified for a small amount of contaminated water.