Violation of pipe laying technology threatens to freeze the water supply in the cold season. The selection of a suitable method is determined by the material from which the pipeline is made and the location of the frozen section. Based on the laws of physics, water is converted from a liquid to a solid state at 0 ° C. To freeze the water supply system underground, it must be cooled to -7 ° C and below.

The consequence of freezing water in the system is cracking or even rupture of the pipe. This is caused by the expansion of the liquid when converted to ice. Further operation of the water supply system becomes impossible. A complete replacement of communications will be required.

Causes

Water in the pipes freezes for several reasons. Among them you can see:

Water in the pipes freezes for several reasons. Among them you can see:

- a sharp decrease in ambient temperature to an extremely low rate;

- pipe laying to insufficient depth;

- immobility of water in the pipeline caused by low or zero flow;

- the pipes are insufficiently or poorly insulated.

The problem of freezing is inherent not only to external networks, but also to those located indoors in the absence of heating.

Troubleshooting Options

There are several methods to fix the problem of frozen pipes laid underground. They are conditionally divided into 2 groups:

- methods of external heat exposure on the problematic section of the pipeline, requiring preliminary excavation;

- ways to defrost pipes from the inside.

The use of the apparatus for welding

Electric defrosting method is popular. It relates to methods of external heating. To get rid of the ice plug in a metal (steel, copper) pipe, a welding machine is used. The method is not suitable for thawing a water pipe made of polypropylene.

Electric defrosting method is popular. It relates to methods of external heating. To get rid of the ice plug in a metal (steel, copper) pipe, a welding machine is used. The method is not suitable for thawing a water pipe made of polypropylene.

The method is based on the property of metals to conduct current. The welding machine, acting on the pipeline, creates an electric field that sets the electrons in motion. Negatively charged elementary particles collide with ions, transferring their own energy. It is converted to heat generated outside.

To defrost a frozen external water system, you will need to unearth it. The terminals of the welding mechanism are attached to each end of the problematic section of the pipe. Then it is turned on by setting the minimum power mode, which is gradually increased. The inclusions of the apparatus for welding should be short-term, not more than 40 seconds. Between them a short pause is maintained. During the manipulation, the degree of heating of the pipe is monitored.

The method allows you to gradually melt the ice cork. First, the water from the tap will begin to drip, then it will flow in a thin stream. This is enough to stop the effects of welding on the pipeline. A thin stream of water pouring continuously will eliminate the remnants of ice in the pipes.

Hot water inside

Defrosting an extended bent pipe in many places from the inside can be done by feeding hot water into it. The technique is also applicable for thawing a frozen sewer pipe.

Defrosting an extended bent pipe in many places from the inside can be done by feeding hot water into it. The technique is also applicable for thawing a frozen sewer pipe.

You will need to use a special home-made device. It is made from:

- wire;

- hydraulic level tubes;

- electrical tape;

- Esmarch's medical mug, consisting of a rubber vessel, a hose and a tap for draining the fluid.

A metal rod, which should be 3-4 cm shorter, is attached to the tube of the hydraulic level. At one end, the tube is attached to Esmarch’s mug, while the other device is pushed into the pipeline until it stops. Hot water is drained from the rubber tank. It will provide a gradual melting of ice in the frozen water supply.A tube with a wire is pushed deep as the ice plug thaws. A bucket is used to collect melt water.

Defrosting a water system through a makeshift device is time consuming. In 60 minutes, 1 meter of pipeline is cleaned from ice.

Defrosting the plastic pipe with a “soldier's boiler”

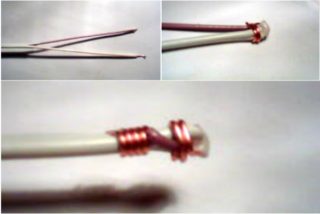

The method relates to methods that warm the network from the inside. Used to warm a frozen pipe made of plastic. It implies the use of a home-made device from a two-core copper wire with a cross-sectional size of 2.5 mm. The principle of its operation is similar to a boiler.

The method relates to methods that warm the network from the inside. Used to warm a frozen pipe made of plastic. It implies the use of a home-made device from a two-core copper wire with a cross-sectional size of 2.5 mm. The principle of its operation is similar to a boiler.

The presence of salt impurities in water gives it the properties of an electrolyte. By immersion in a pair of electrodes to which voltage is applied, they are heated.

To build a "soldier's boiler" follow the instructions:

- Separate the cores at one end of the wire.

- Each of the cores will need to be exposed and wrapped in 5 turns around a metal tube. Between turns maintain a distance of several millimeters. They should not be in contact with each other. Otherwise, there is a risk of short circuit.

- The other end of the copper wire is connected to the plug.

A home-made boiler is introduced into the pipeline until it is stopped by an ice plug. Then, current is supplied by inserting the plug into a power outlet. Thawed water is blown out by the compressor.

Hot steam application

Hot steam will help warm frozen plastic pipes from the inside. It has a higher temperature than hot water.

The steam method involves the use of an autoclave. You will need to perform the following sequence of actions:

- A hose that can withstand high pressure is attached to the fitting of the autoclave.

- The autoclave is filled with water (no less than a bucket) and put on fire.

- The hose is inserted as deep as possible into the pipe.

When the liquid boils, the supply of hot steam to the frozen pipe begins under pressure. The ice will quickly melt.

Internal heating by hydrodynamic unit

The most effective way to warm a frozen water supply system from the inside is to use a hydrodynamic installation. It involves calling professionals with special equipment at home.

The most effective way to warm a frozen water supply system from the inside is to use a hydrodynamic installation. It involves calling professionals with special equipment at home.

In addition to defrosting pipes, a hydrodynamic installation is used for the preventive washing of the water supply system and sewer system. Equipment under pressure delivers hot water to the pipeline having a temperature of the order of + 150 ° C. The installation requires diesel fuel and electricity (power 7 kW, voltage 380V).

When and which method to choose

The external heating method by the welding machine is applicable for bent in many places extended water supply systems made of metal. In such cases, it is not possible to break the ice with wire.

To heat plastic communications, it is preferable to use methods that work from the inside. We are talking about the use of hot water or steam, heating the liquid directly in the pipe. The external method of thermal exposure to the problem area with a welding machine is unacceptable.

Complex cases require the use of powerful professional equipment.

The problem of freezing the water supply system is familiar to many owners of private houses who encounter it in the cold winter months. It requires an immediate solution on its own or by seeking the help of professionals.