Drainage wells are part of the sewer network of the same name, which is necessary to drain excess underground moisture. Subsoil sources without control destroy the foundation and degrade soil productivity. Devices differ in function, this must be taken into account during installation.

Purpose of a drainage well

Excessive moisture in the ground causes low yields, the death of horticultural crops and the destruction of the foundations of buildings. If the groundwater on the site is high, or the area is famous for the abundance of rainfall, the installation of a drainage system with mandatory arrangement of wells is required.

Sometimes they confuse storm sewers with drainage, but they differ. The first purpose is the removal of sedimentary water from the surface. Drainage removes moisture from the depths of the earth, so the drains are laid below the foundation level and sent to the collector well.

In addition, well tanks help to clean pipes from silt sediments and other sediments. When liquid enters the well, impurities settle on its bottom. The sedimentation area should be located at least 400 mm below the drain connection level.

Types and device

Accumulative (collector) wells are located in the lowest places of the drainage system and serve as the final points of sewer branches. They are mandatory if the opportunity is not given to quickly drain excess moisture into a ditch or pond.

When installing a drainage system on the site, it is not enough to equip only a sump for the accumulation of effluents. Other well devices will be required. They are:

- rotary;

- inspection or revision;

- absorbent.

Rotary devices are equipped for cleaning and maintenance of pumping units. Wells put on every second turn of "rain showers". Variety - differential constructions, erected on terrain with uneven relief.

An inspection well is required to verify the functioning of the network. They are placed on the upper points of the sewer line. Observation structures vary in size. A construction with a diameter of 300 mm is enough for a television inspection, but if a full inspection is planned, it is necessary that a person can freely go down to the well. Revision can also perform the functions of a rotary device.

Absorption plants are being built in the wettest places. There is no bottom; water is cleaned by a gravel-crushed stone pad, which is covered by filtration material. The recommended section of the well is 575 or 695 mm, and if a person needs to get there, the diameter needs at least 900 mm.

The maximum distance between the wells is 50 meters. They must be installed on sections of turns, changing angles and combining two or more drainage branches.

Observation and absorption systems are usually mounted vertically, while storage systems are also installed horizontally.

Manifold wells are equipped with a submersible pump. The capacity of the pumping unit is from 100 liters per minute, its cost is from 5000 rubles. Pumps with more power are chosen for industrial facilities or collectors. A pump system will not be required if the drainage system is laid out on a slope, which ensures gravity drainage to a nearby beam or pond.

Material of manufacture and price

Wells for drainage are made of reinforced concrete rings, plastic pipes or barrels, bricked.

On a small, not waterlogged area, the structure can be erected from old car tires. But it will not be as high-quality as options from other materials.

Concrete and brick wells are durable, but to seal them you need to cover with special compounds. For the installation of reinforced concrete rings, special equipment is required - they are heavy.

The most favorable price-quality ratio for polymer structures.

Drainage wells can be purchased ready-made, with technological holes for groundwater discharge, a neck, adapters, sealing elements and a manhole with a cover. For durability, such structures are corrugated - this allows to withstand high soil pressure. Absorption devices are coated with perforations.

In the form of plastic products are:

- conical;

- cylindrical;

- rectangular.

Due to their low weight, they can be installed manually. The easiest way is to install conical wells - the walls of the pit tilt less when sloping.

You can not buy a finished well, but make it yourself from double-walled corrugated or twisted pipes. The question is how appropriate it is.

The cost of polymer structures is low. For example, the prices for narrow viewing drainage wells of the TeraPlast company start from 1600 rubles. The finished revision design with a hatch and a welded bottom, wide enough to allow a person to descend calmly into it, will cost 11,000 rubles. For comparison, an order for a well device made of reinforced concrete rings will result in no less than 15,000 rubles.

Installation Rules

For arranging the drainage complex, polymer perforated corrugated pipes with a geotextile winding, easy to install, are suitable.

For arranging the drainage complex, polymer perforated corrugated pipes with a geotextile winding, easy to install, are suitable.

The cross-section of the pipe segments and the outlet well holes must match. Standard diameters range from 50 to 200 mm.

At the break points of the network, rotary devices are installed, and at the connecting nodes - revision devices. The sewage line ends with a place where all pipes converge - with a filtering or storage well, from which forced or natural drainage of moisture is carried out.

Depending on the type of well and the selected material, the installation technology is determined.

Plastic storage or manhole

Corrugated pipe or a sealed container of suitable sizes is suitable as a material for installation.

Step-by-step instructions for manufacturing the device:

- Dig a pit in size a little wider than the tank.

- The required length of the corrugated pipe is measured, then it is cut.

- Using bitumen, a plastic bottom is fixed on the pipe section.

- A sand cushion is poured into the pit or a solid base of concrete is prepared.

- At the bottom, put the collected container. Pipe bends can be cut out after the tank is installed.

- Make a connection to the well of the pipeline and seal the cracks.

- The gaps between the well and pit walls are covered with gravel, sand or a cement-sand mixture.

Self-assembly of the audit device is carried out according to the same scheme, except for the installation of pumping equipment.

Filtration plastic well

For an absorption plant, a plastic tank without a bottom or pipe will be required. You can choose perforated products or saw holes in the lower part yourself. Installation is carried out in a manner similar to mounting the drive, only without pouring the base of concrete. Instead, a filter system is installed at the bottom of the well.

A cushion of gravel, crushed stone, or a similar material 0.2–0.3 m thick is poured into the pit; A pipeline is connected through the top of the well, the installation is covered with gravel or gravel on all sides.

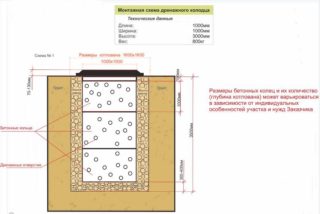

Well of concrete rings

Installations of any type are created from this material, but if an absorption option is proposed, the bottom or concrete screed is not necessary.You will need a filter layer according to the scheme described above.

Installation steps:

- Dig a pit of the necessary size.

- At the bottom of the pit, a sand and gravel pillow is covered. If a filter chamber is mounted, the layer thickness should not be less than half a meter.

- The first ring is mounted on the pillow. When choosing elements without a bottom, a concrete screed is made.

- The remaining rings are laid, the seams are closed with a concrete solution or bitumen.

- Holes are made in the last ring, pipes are inserted into them, after which they thoroughly seal all the cracks.

- From above, the well is covered with a hatch with a lid made of plastic or metal, since concrete products have a large mass.

- Sand, gravel or crushed stone are poured into the voids between the walls of the pit and the reinforced concrete rings.

For the construction of wells, reinforced rings with a lock are ideal. In their absence, ordinary concrete products are also used. The thicker they are, the longer they will last.

The uninterrupted operation of drainage in the autumn and spring periods is facilitated by the regular cleaning of wells from sludge with the use of a stick length, an irrigation hose. Installing a tight cover on the hatch of the device helps to reduce pollution.