For high-quality drainage of water from the soil, installation of a drainage system is required. The construction works by gravity, providing an optimal level of dryness / moisture of the soil. As the main element of the drainage system, a plastic drainage well KDN is used. The polymer design has proved to be the best, even under the condition of many years of operation. As a result of a well-drained soil, stone buildings on the site remain durable, it becomes possible to carry out construction work, as well as plant various vegetables / fruits in the soil and receive a further crop.

Types and arrangement of plastic wells for drainage

Plastic viewing KDN for drainage is divided into groups according to their purpose:

Plastic viewing KDN for drainage is divided into groups according to their purpose:

- Revision, it is also a viewing / inspection. Designed to control the level of water in the soil and the degree of clogging of the system.

- Turning. It is installed in places of sharp bends of the drainage structure at an angle of more than 30 degrees.

- Linear. A well designed for installation on direct long lines of the system. The minimum distance from one to another direct element is 40-50 m.

- Overflow. It is used for installation in very elevated areas, when drainage pipes have a significant difference in height. That is, located at different depths.

- Cumulative, it's collector. Works as a reservoir for the accumulation of ground / storm water. The storage unit is mounted in the lowest and dead end of the drainage system. The water collected from the site can be used in private life (watering, irrigation).

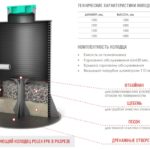

- Filtering, it is absorbing. This is a well that does not have a sealed bottom. Instead, a pillow of sand and gravel is poured to filter the waters and then send them to the ground. As a result, the accumulated moisture goes into the soil at the lower point of the site. Such wells can be used only with small volumes of groundwater - up to 1 cube in 24 hours.

The drainage system must be mounted on a slope so that groundwater leaves the site by gravity. Pipes are laid below the level of soil freezing. The slope is made at the rate of 5-7 mm per 1 linear meter of the system. If for technical reasons or due to the relief of the site installation of a sloping structure is not possible, the collector tank is equipped with a pump for the forced movement of water.

- Swivel well

- Plastic

- Revision Well

All the main elements of the drainage system are classified according to the material of manufacture. Wells are made from these types of plastic:

- PP (polypropylene). Durable, wear resistant material. It becomes extremely brittle and even undergoes deformation at prolonged subzero temperatures in combination with mechanical stress.

- PVC (polyvinyl chloride). It is considered the most durable material for the production of wells. Inert to aggressive media, which are present in excess in ground / rain water. Often, tanks made of polyvinyl chloride are even used for the installation of drainage systems in industrial enterprises.

- PE (polyethylene). Ideal material for the installation of a drainage system on moving soil. It is able to freeze at minus temperature indicators and at times of thaw return to its usual state without loss of elasticity.

When choosing a polymer well for a drainage system, you should rely on temperature indicators in the region and on the type of soil on the site.

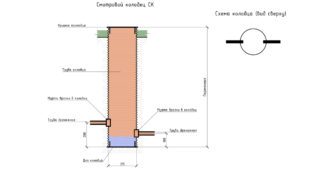

The device of the drainage system and polymer wells:

- perforated pipes located throughout the section and brought to revisions;

- the well itself, having a cone-shaped top with a hatch, a corrugated “body” is sealed or with couplers for introducing pipes, a polymer bottom or a tray for arranging a sand-crushed stone pillow.

It is possible to purchase plastic drainage KDN both in a full complete set, and with separate elements.

Advantages and disadvantages

The main advantages of polymer drainage wells are as follows:

The main advantages of polymer drainage wells are as follows:

- low weight, which allows you to easily mount the entire system, even alone without the involvement of special equipment;

- corrugated surface acting as stiffeners;

- inertness to aggressive environments and anti-corrosion properties;

- rated load up to 80-90 tons;

- long service life reaching 50-70 years;

- the possibility of using pipes as reservoirs for an autonomous septic tank.

As for the shortcomings, the strict observance of the system installation rules can be considered a relative minus. Otherwise, the well will eventually be deformed under the influence of soil layers.

Mounting technology

In order for the drainage system to work without failures, it is important to strictly observe all stages of its installation. They act in the following order:

In order for the drainage system to work without failures, it is important to strictly observe all stages of its installation. They act in the following order:

- In the area, in accordance with the project, trenches are being digged for laying perforated drainage pipes. Be sure to make a given slope within 5-7 mm / linear meter. The bottom of the trenches is covered with a sand cushion 5 cm high.

- Under the wells arrange pits. The depth of each should be equal to the height of the polymer viewing / rotary / storage corrugated pipe plus 20 cm per cement pillow device.

- The bottom of the finished pit is covered with a layer of sand 5-7 cm, and then a layer of concrete mortar is poured on top. Its thickness is 10-15 cm.

- A well is installed on the finished solidified base, having previously formed holes for pipes in it. These places are equipped with special gaskets.

- The pipes of the drainage system are connected to the nozzles. All joints are carefully coated with sealant.

- The walls around the installed well are covered with a mixture of crushed stone and sand in a proportion of 1/1. The mass is moderately tamped with backfill. This will fix the tank in the ground.

- The top of the audit is covered with a hatch.

If the well cover will be located at ground level, you can equip it with some kind of identification mark, so that later it would be easy to navigate on the site and find it.

The cost of plastic drainage wells

The prices of plastic filter wells for drainage vary depending on the cross section of the pipe and its length:

| Name | Well size (diameter / length) mm | Price, rub.) |

| Corrugated plastic cdn | 300x1000 | 950 |

| Plastic drainage KDN corrugated | 300x2000 | 1 850 |

| Plastic cdn | 300x3000 | 2 800 |

| KDN | 300x4000 | 3 750 |

| KDN drainage plastic | 368x1000 | 1 300 |

| Polymeric drainage KDN | 368x2000 | 2 550 |

| Corrugated well | 460x1000 | 2 000 |

The maximum diameter of the well can reach 1 meter. Its largest length is 6 m.

In order to acquire the water pressure of the desired length, it is important to know the level of groundwater occurrence in the area. To do this, conduct geodetic studies or simply find out information by the method of home drilling.