The Japanese company Makita produces high-quality equipment and tools, including submersible drainage pumps. The difference from analogues is that they are able to pump out liquid with a large number of grains of sand of various sizes, pebbles and other solid impurities. The model range of the equipment offered is large: when selecting a pressure device, technical characteristics must be taken into account.

Application area

Japanese brand pumping devices are used for such purposes:

- sewage pumping;

- pumping out during floods;

- pumping and cleaning of wells and wells;

- use as fecal pumps in the absence of a central sewage system.

In the process of pumping wastewater, the pump takes them to an external sewage system or to a sewage treatment plant. It is not recommended to use if a large number of fibrous compounds are present in the drains.

Water with a high temperature - up to 35 degrees - is pumped out with a periodic shutdown of the pump so as not to overheat the engine.

Principle of operation

Pumping out of drains is carried out using a hose, which drops to the bottom of the tank. The pumped liquid is discharged through the outlet pipe.

At the bottom of the device there is a hole for collecting wastewater. The bottom of the apparatus is protected from stones and large particles by a mesh filter.

To work in standalone mode, the trigger is connected to a float, which controls the level of liquid in the tank. If it goes below a certain point, the float drops and works like an emergency switch.

The device is equipped with reliable electrical insulation, which prevents the risk of short circuits.

Lineup and Specifications

All variants of pumping equipment of this brand do a good job of pumping dirty water with solid fragments up to 3.5 mm. But each model has its own advantages and design features:

- The PF0300 has a flow rate of 140 l / min and raises the fluid to a height of 7 m. The device is widely used in garden irrigation systems. Not afraid of solid contaminants up to 5 mm.

- PF0410 is used in open sources, in flooded basements and drainage systems. Differs in small weight at high efficiency - 8400 l / hour. Installed thermal protection.

- PF0610 is commonly used for watering and pumping pools. The maximum lifting height is 7 meters. Productivity - 180 l / min.

- PF1010 features a silent electric motor. Thanks to the power of 1100 watts, it is able to supply water to a height of 10 m, immersing 5 m.

- PF1100 pumps over 15,000 l / h. The highest pressure of the liquid is 9 meters. Used for contaminated liquids with impurities up to 5 mm.

- PF1110 is capable of pumping out both clean and contaminated liquids. With its help, it is convenient to irrigate garden crops with rainwater from a storage tank. Equipped with double seal system and oil chamber for short idle operation.

The most effective and ergonomic for use in domestic conditions is the PF0800. With a relatively small size, it has high performance.

Installation Features

Before installing the device, it is necessary to inspect the casing element. Curved, narrowed, uneven pipe leads to a reduction in the operational life. If large flaws, due to the difference in cross section, the speed of the water flow, which cools the system, decreases and the pump burns out.

Before installing the device, it is necessary to inspect the casing element. Curved, narrowed, uneven pipe leads to a reduction in the operational life. If large flaws, due to the difference in cross section, the speed of the water flow, which cools the system, decreases and the pump burns out.

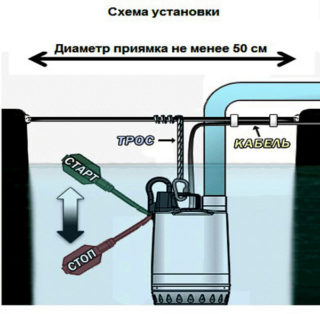

Makita drainage pumps for dirty water are installed as follows:

- The pressure device is fixed on a rope of kapron with high tensile strength. So that the mounting unit does not get into the water intake, it is made at a distance of 10 cm from the input. The ends of the cord are carefully melted.

- When the device is immersed to a depth of less than 10 m, an immersion suspension is attached to the ends of the rope to prevent vibration. For these purposes, a medical tourniquet or tape made of flexible rubber is used. Do not use a wire or cable made of steel, so as not to damage the mounting on the pump housing.

- The electric cable, suspension and pipe made of metal-plastic are interconnected by means of an insulating tape in 0.6–1.2 m.

- If necessary, a non-return valve, stop valves and elbows are mounted.

- The unit is lowered into the well. This is done so that it does not touch the walls. If there is a risk of contact, the case is wrapped with rubber.

It is not recommended to lower the pump below the depth specified in the documentation. This reduces performance and makes it difficult to quickly pull the device out.

The peculiarity of Makita brand submersible pumps is also that for pumping wastewater it is not necessary to place the device in the mine. It can be placed nearby and pumped through a hose. All equipment can be easily transported. And if there is a slight breakdown and malfunction of the device, it is easy to disassemble and repair.