Contaminated domestic, household and industrial wastewater is treated before being discharged into natural water bodies. At the first stage, mechanical decontamination is performed using grates and nets. Then, the liquid fraction is sent to sedimentation tanks, where solid organic waste, which makes up 35% of the contaminants, is separated. Drains with dissolved organic matter are sent to aeration tanks - tanks with a rectangular horizontal section, filled with activated sludge, where further biochemical water treatment takes place.

Types and principle of operation of aeration tanks

Wastewater entering the aeration tank is mixed with activated sludge using air bubbles supplied through an aeration system consisting of various types of aerators. In this case, the mixture is saturated with oxygen, which is necessary for the life of the population of microorganisms that make up the biomass of activated sludge. They absorb up to 85% of dissolved organics. The biomass in the tank increases due to their nutrition and reproduction. With constant mixing, a uniform oxygen concentration is created throughout the tank. With its help, bacteria turn waste into carbon dioxide and water.

Wastewater entering the aeration tank is mixed with activated sludge using air bubbles supplied through an aeration system consisting of various types of aerators. In this case, the mixture is saturated with oxygen, which is necessary for the life of the population of microorganisms that make up the biomass of activated sludge. They absorb up to 85% of dissolved organics. The biomass in the tank increases due to their nutrition and reproduction. With constant mixing, a uniform oxygen concentration is created throughout the tank. With its help, bacteria turn waste into carbon dioxide and water.

At the exit from the aeration tank, water containing a minimal amount of dissolved organic matter, together with the sediment that is formed during the life of microorganisms and bacteria, passes through the sump system. The sludge from the secondary sumps is sent to the poultry mill, and then replenishes the amount of activated sludge. After the final sump, clean water is discharged into the reservoir.

The technological scheme with a clarifier - a supercharger with natural aeration - more effectively traps pollution and withstands peak loads than the use of conventional vertical sedimentation tanks.

The principle of operation of mechanical aerators is to capture air from the surface while mixing the liquid, pneumatic - to supply air from the compressor. Combined aerators allow using mechanical devices to crush air currents in water.

The main factors affecting the cleaning system:

temperature condition;

- continuity of supply of source water;

- degree of oxygen saturation;

- toxic substances;

- the level of acidity of the medium.

To remove ammonia nitrogen from industrial or commercial effluents, the nitrification process is applied using aphthotrophic bacteria that feed on inorganic carbon. As a result, nitrites and nitrates are formed in water, which are removed with the help of bacteria - denitrifiers, heterotrophic bacteria that decompose harmful compounds to free nitrogen and use bound oxygen for their vital functions.

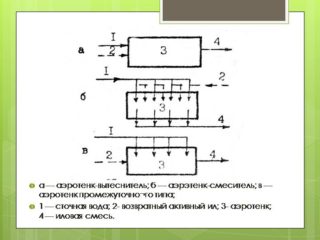

Several types of aeration tanks are distinguished depending on the method of supplying wastewater and activated sludge, and draining treated water.

Aeration tanks mixers

Designed for the treatment of industrial effluents having a high concentration of pollution - up to 1000 mg / l. They allow cleaning to be carried out in case of non-uniform flow of wastewater and a change in its composition, the principle of operation of aeration tanks for wastewater treatment is to supply water and sludge through openings along the entire length of the tank. Purified water is discharged evenly. At the same time, better mixing of sludge with source water is achieved, at which biochemical treatment is accelerated.

Displacement aerotanks

Used for the treatment of urban and domestic industrial wastewater.Activated sludge and polluted water are supplied from one end of the aeration tank, which, as they move, are mixed under the action of aerators and sent to the outlet of the tank. The rate of decomposition of organic matter decreases as it moves forward, as the amount of organic matter decreases. At the outlet, purified water enters the sumps, and the sludge mixture is discharged through the outlet for further use.

Used for the treatment of urban and domestic industrial wastewater.Activated sludge and polluted water are supplied from one end of the aeration tank, which, as they move, are mixed under the action of aerators and sent to the outlet of the tank. The rate of decomposition of organic matter decreases as it moves forward, as the amount of organic matter decreases. At the outlet, purified water enters the sumps, and the sludge mixture is discharged through the outlet for further use.

The main disadvantage is a decrease in the quality of treatment with a sharp change in the content of organics and toxic substances. With a uniform flow of waste water, the use of displacer aeration tanks is preferable due to the small volume and simplicity of the design. They are divided into sectioned and corridor.

The former are used in aerotanks longer than 60 m. At equal intervals, the corridors are divided by partitions to prevent a change in the direction of movement of the source water.

Corridor aerotanks are called displacers with a ratio of the width of the tank to its length of 1:50. If the width is 6 m, then the length is 300 m, respectively, with a width of 9 m, the length is at least 450 m. For compactness, double-corridor aeration tanks are made if the tank occupies more than half the volume of treatment facilities. The use of three-corridor structures allows working without sludge regeneration.

Aerotank displacer with regenerator

For a more intensive process of organics oxidation, aerotanks displacers with built-in regenerators are used, where the dosage of activated sludge is increased by two to three times, which allows to increase the quality of cleaning.

Aerotank in a septic tank

Owners of private buildings for effective wastewater treatment make an active septic tank. It requires a large volume, has a simple design and high purification of domestic wastewater - up to 99%. Aerobic microorganisms have higher productivity than anaerobic bacteria present in cesspools. To increase the number of aerobes, an aeration system is connected to the septic tank and a compressor is installed.

The quality of wastewater clarification in aeration tanks must comply with SNIP 2.04.03-85.

Install and run a cleaning system

For the installation of a wastewater system, it is recommended to invite third-party specialists or a manufacturer, as the project has design features.

For the installation of a wastewater system, it is recommended to invite third-party specialists or a manufacturer, as the project has design features.

Installation begins with digging a foundation pit under an aeration tank. To create a pillow, a layer of sand up to 20 cm high is poured at the bottom. After that, a tank is installed. At the same time, the tank is filled with water and the tank is filled up, and the water level should be 15 cm above the ground level to prevent deformation of the tank under the pressure of bulk soil.

At the next stage, communications are laid, a compressor is installed and connected to the aeration system. The entire structure is covered with earth. After checking the operation of all systems and the control start-up, the aeration tank is put into operation.

Advantages and disadvantages

The main advantages of the installation:

The main advantages of the installation:

- high quality wastewater treatment at high speed;

- compactness combined with simplicity of design;

- full load of equipment;

- no need to insulate the object, since redox reactions occur with the release of a large amount of heat;

- no unpleasant odor.

Minuses:

- high price;

- energy costs for aeration system;

- the need for operating personnel for maintenance.

For the normal functioning of aeration tanks, a continuous supply of wastewater with dissolved organic substances for the nutrition of microorganisms is necessary. With the shutdown of the system in the absence of oxygen, rotting processes begin, aerobic microorganisms die.

With a decrease in air supply, formation of deposits is possible.The minimum oxygen concentration to maintain the vital activity of microorganisms should be higher than 0.2 mg / cubic dm, for effective biochemical treatment - 0.5 mg / cubic dm.

The aeration system is selected at the design stage. The calculation of the volume of aeration tanks is determined on the calculator from the product of the maximum flow rate per hour of peak load for the duration of the drains in the tank. The speed and quality of cleaning is influenced by the size of the air bubbles supplied from the compressor. The smaller their size, the better the oxidation process. There is an active increase in biomass, microorganisms better tolerate the effects of toxic substances. On the other hand, the fine-bubble fraction does not allow sufficient mixing of activated sludge, which leads to the appearance of deposits in the “dead zones”.

To increase the intensity of mixing, motive nozzles are installed on the walls of the aeration tank, creating a turbulent circulation of flows. They increase the rate of rise of small bubbles and shorten the interaction time of effluents and activated sludge. Aeration tanks with a wall-mounted aeration system work more efficiently than models with an aeration unit at the bottom of the tank.