The modern gas solenoid valve is a type of shutoff valve and is used to control the flow of gas and liquid in the pipeline system. Details are divided into several types, each of which has its own characteristics. When choosing a valve, it is necessary to take into account its scope of application, selection criteria and nuances regarding installation.

Purpose and device

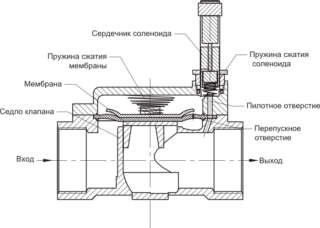

A gas valve of this type can be either a control valve or a shut-off valve; it is controlled manually or by an automatic system. By design and purpose, this element resembles its standard analogue with the difference that the locking part in it is driven by an electromagnet supplemented by a movable core. During the supply of voltage to the coil, it begins to push or retract the core, which is connected to the rod. Such a part is intended for use in industrial installations, domestic heating systems and in the field of water supply. The valve device has a standard design:

- case with two nozzles;

- chamber with a saddle;

- locking part of a dish-shaped, petal or spherical form;

- return spring;

- rod for connection with the locking part and the core;

- solenoid.

The enclosure for installation is made of metal alloys of a non-magnetic type or durable plastic. Its optimum tightness allows the valve to be used in a variety of environments. The part is controlled by wires that are connected to the electrical contacts of the sensor located on the outside of the housing.

The valve must meet the desired level of resistance to noise, vibration and electromagnetic fields.

Gas valve classification

The solenoid valve for domestic gas is divided into categories depending on external features, the working environment, the method of operation and installation, as well as a number of other nuances.

By type of performance

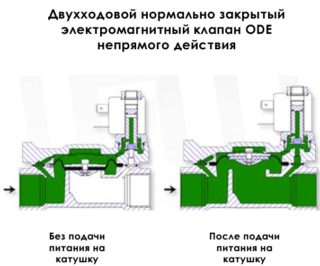

Given the position of the main element and its circuit, the gas shut-off valve can be normally open or closed. In the first case, the passage will open for gas or liquid in the element, when voltage is applied, it will automatically close, in the second case, this process is the opposite. In addition to such devices, there are their universal counterparts that work in two directions at once.

By type of work environment

With this parameter in mind, valves of this type are produced specifically for operation in air, steam, water, oil and lubricants or in an active environment. Devices operating in radiation conditions are made of special resistant materials.

According to the features of operation

According to the characteristics of the external environment, a gas solenoid valve is available for operation under ordinary conditions, especially for rooms with a high level of humidity, and functioning at high and extremely low temperatures. The valves are also complemented with explosion protection provided by special parts and materials.

According to the principle of action

The principle of operation of the magnetic valve depends on the type of voltage of the coil, which can be with alternating or direct current. Elements of the first type are used for high pressure trunk pipelines, the second - for pipes with a small cross section and low pressure.

From the number of saddle strokes

The functioning of the element is affected by the number of strokes, depending on which it can be a one-way, two-way or three-way, taking into account the number and type of shutter nozzles. Depending on the design, they are incoming and outgoing.

By type of management

The solenoid valve for domestic gas works in two ways, according to the type of control, such valves can be direct or indirect. Parts of the first type are designed for environments with a complete lack of pressure, their analogues of the second type are supplemented by a pilot element, which works automatically when there are differences in the environment at the inlet and outlet.

By type of functionality

The functionality of the valve depends on the material of which it is made. Most often, such elements are made of elastic polymers of various groups, which are made by special technology. Due to their high strength, they withstand temperatures from -40 to +250 degrees.

Principle of operation

The operation of the device is based on the principle of electromagnetic instructions, when current flows through the coil, a magnetic field is formed inside it, affecting the core, depending on the position of which the shutter element opens or closes. The valve on any gas pipe can have different control voltage. Devices with a low level are characterized by low power, so they work due to low-voltage semiconductor circuits. Such valves are used in low-pressure systems, in gas pipelines with small diameters.

Drives operating on alternating current are considered more efficient, for this reason they can be installed on high-pressure trunk pipelines.

Scope of application

The standard electromagnetic gas valve has a wide range of applications and can be used in all areas where there is a need to control the remote flow of liquids and gases. This list includes heating, water treatment and water supply, irrigation and sewage systems, household appliances, pipeline transport. The device is rarely used for vehicles, but its relevance is increasing in other industries.

Valve Selection Criteria

To choose a valve capable of regulating the flow of liquid and gas in full force, you need to pay attention to the main parameters. The main criterion is the working pressure of the part, which must correspond to the system in which it will be installed, the limit value can reach 200C. In addition, take into account the diameter of the connection, measured in inches or millimeters. It is worth remembering that often the cross section of the device is less than the conditional passage. You will also need to take into account the environment in which the part is used, which must be compatible with the material from which it is made, and the voltage of the valve coil of 24 or 220 volts.

Instrument Installation

The valve is connected by specialists or independently, if they have the appropriate skills and qualifications. First, the principle of connecting the part, which can be threaded or flange, is determined.

In the first case, the outlet and inlet pipe will be supplemented with external or internal thread and fittings through which fittings are built into the pipeline, this method is considered more convenient for do-it-yourself installation.

In the second case, the nozzles and pipe ends are supplemented by flanges pulled together by bolts. This option is more often used for high or medium pressure lines. Before installation, you will need to mark, cut and strip the pipes, as well as select a suitable location for the device. The device is connected in accordance with the directions of the arrows printed on its body, which indicate the direction of flow.

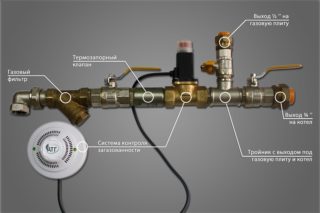

The piping system must be supplemented with a filter to prevent contaminants from entering.When connecting the valve, the safety rules and recommendations of professionals must be observed.

Advantages and disadvantages

The electromagnetic gas valve has many advantages and almost no disadvantages. Its main advantage is the ability to quickly and remotely control flows in a working environment. With it, you can connect to an automated and centralized control system, which significantly increases the efficiency and accuracy of regulation of parameters compared to manual operation.

The element helps to significantly reduce the cost of technological processes, increase production safety and reduce the impact of hazardous factors of the production environment, as well as increase the efficiency of various devices and installations. The solenoid valve actuator is not equipped with gear and worm gears, due to which its reliability and ease of operation are significantly enhanced.

The main disadvantage of the device is the lack of the ability to smoothly control the opening of the shutter, which can only be in the open or closed position.