Rocker switches are hand-operated devices that produce several commutations in a single movement. They are used in switchgear, close and open the circuit. The cross over switch is designed for current strength of 100-1000 A and voltage up to 400 V, suitable for residential and industrial premises.

What is a rocker switch

The purpose of the rocker switch is to transfer voltage between two lines or to connect several networks. Using a knife switch, it is possible to eliminate current leaks in accidents and quickly switch to a whole line. Switching the device is carried out using the lever on the front panel, which is brought in 1-2 positions.

The equipment is installed in the switchboard room or near the input panel.

Device specifics

The switch of the cross over type is similar to the on / off switch according to the principle of operation, but differs in the increased power and smooth knife drive. The second difference is the process of switching with a line break and work in three positions:

- home / home network;

- shutdown;

- power from the generator.

To understand the principle of operation of the cross over machine, you need to understand the design. The middle contact is the rail in the middle with V-shaped knives. As lateral, the upper and lower terminals are used. The middle contact connects only to the top or only to the bottom. The knives do not have accelerators or springs, so the transfer from the main to the backup network is done manually.

Pros and cons of using knife switches

The electro switch is the simplest device, which is characterized by advantages and disadvantages. The advantages of operation include:

- Visibility. The device can be inspected visually for damage. The position of the knives is clearly visible.

- Simple construct. A small number of nodes simplifies maintenance and repair of the device.

- High switching current. The switch commutes a current of 500, 630 or 1000 amperes.

- Low cost. You can buy a switch for installation in a private house or apartment.

Despite the positive characteristics, the machine has several disadvantages:

- Open type of construction. All elements are in sight, with careless contact there are risks of electric shock.

- Abnormal switching speed. If the knives are moved slowly, a high-temperature arc forms, which burns out the internal components of the device.

- Possibility of a short circuit when a high-temperature arc appears.

- The occurrence of inrush currents when switching to turn off the load.

To protect the exposed parts, the cross over relay is hidden in a special box.

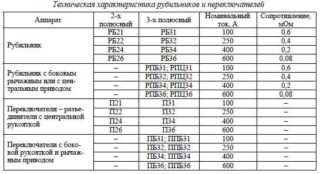

Types of knife switches

Connecting devices according to various schemes and differences in operating parameters imply the division of knife switches into types.

Single pole circuit breakers

Devices have one module and copper conductors. It features a low output voltage of about 200 V. The main application of the toggle circuit breaker is to service the generator with an operating frequency of up to 20 Hz.

A modular appliance is not installed in a residential building that consumes a lot of energy.The maximum load of the device should not exceed 200 A.

Bipolar modifications

The purpose of the cross over switches in two directions is the maintenance of high-rise buildings, equipment connected to a two-phase or single-phase network. The device has an average negative resistance rating of 60 ohms. The type of output voltage depends on the modification of the switch.

The switch is suitable for connection to a two-phase network. Equipped with blockers, has a high sensitivity limit. Available with two or three modules. Suitable for generators are models with a voltage of 350 V, designed for a load of 30 A. Installation is carried out in conjunction with a power supply unit of 200-300 A with a load limit of 3 A.

Popular two-terminal devices are PP20 with open type capacitors, which require the connection of a 300 V power supply.

Dual Capacitor Switches

The changeover switch is designed for single-phase circuit type only. The devices are available with two capacitors and two modules, work together with 300 V power supplies. The average voltage rating is 30 A.

The devices are installed using two copper jumpers. Dual capacitor models are only compatible with expansion switches.

Devices can be combined with counters.

Cross over switches

An electric switch provides a disconnection of the network from one energy source and connection to another. The presence of a midpoint explains the name “cross over”. Devices are available with arrester, providing switching when the voltage is connected. Models without arcing mechanisms are switched when the load is turned off. The switch works only in manual mode - switching is carried out using an isolated control lever.

The design of the device is presented:

- sealed housing;

- movable knife contacts with two working positions and one intermediate;

- interrupter chamber, but there are knife switches without it;

- terminals for connecting to the network.

Switching on to one load line is carried out according to the principle:

- The main power supply is connected to pin No. 1.

- A diesel or electric generator is connected to pin No. 2.

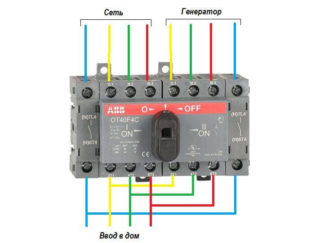

If commissioning with a three-phase voltage is required, a three-phase switch with 4 poles is used. The device is connected as follows:

- The power supply must be entered through 4 terminals.

- At 4 terminals, the generator pops up.

- The 4 terminals connect a load.

Zero is connected to one of four terminals, and phase is connected to three.

Areas of use

The main purpose of the devices is to transfer the load between two or more sources. They are operated with the aim of:

- switching backup power supply;

- transfer of load from the main equipment to the backup;

- switching from one source to the second without the load.

The switch speed of the switch should not depend on the operator - this will prevent the burning of contacts.

Features of the use of the three-position switch

A three-pole breaker is suitable for connecting backup power to the home line. It is used only after disconnecting the load. The generator will need to be activated and put into working position. Then you need to connect the house network to it. When carrying out repair work, the switch will be used as a disconnector.

Mounting devices

The cross over electric equipment establishes in a switchboard. For internal installation, models with a plastic case are suitable, for external - metal. Inside the boxes there is a special DIN rail for knife switches. Installation of devices is as follows:

- Models that turn off under load are installed vertically.

- The type of tires and wires is selected. Their cross-section should correspond to the current rating of the switches.

- Tires and wires are connected to fixed contacts.

- The elements are tightly clamped with terminals for reliable contacts and eliminating the possibility of overheating.

- The thread of nuts is covered with petroleum jelly.

- Contact nuts tighten smoothly. After the first turn of the wrench, the nut is loosened, and then gently tightened.

- Castor oil is applied to the surface of the contact knives, which will prevent them from jamming in the racks.

- Grounding of metal non-conductive elements on the outside of the box is carried out.

In order for the switch to work without failures, installation is carried out indoors. The device must be protected from moisture, and then check the strength of the fit on the din rail.

Inclusion order

Three-position, or packet devices are available without a disconnector. They connect like this:

- Introductory machine stop.

- Installation of the device handle on the generator line.

- Turning off the load automat.

- Connecting the switch cable to the generator outlet.

- Starting the generator, waiting for warm-up (2 min).

- Power supply to the switch.

- The inclusion of automatic load.

Automata are placed on each of the inputs.

Basic wiring diagrams

The circuit breaker connection scheme is determined by the type of power supply.

Single phase network

Only bipolar modifications with power supplies with an operating voltage of 300 V are connected to this line. Connection is made at a negative resistance rating of 50 Ohms. Devices are placed on jumpers made of copper. Installation in a residential building is carried out in switchboards of type KK220.

Reversible blocks for a single-phase network are not suitable.

Biphasic line

For a two-phase network, only expansion switches are suitable. You will need to add a connecting node to them - power supplies of 220 V. The limit voltage of modular devices is 300 V, but the presence of two modules allows an output voltage limit of 350 V.

The process of connecting the switches has several nuances:

- the lock is placed in the electrical panel together with the thyristor unit;

- the negative resistance rating is 40 ohms;

- contact systems are used only in closed circuit breakers;

- if there are two reversible blocks from different manufacturers, you will need a controller.

The controller is used to prevent non-linear network distortion.

Three Phase Power

The switch is combined with a power supply with a rated voltage of 400 V, pulse transformers. You can enter the device through the inverting output. Output currents will be supplied through feed-through capacitors.

For a three-phase network, it is allowed to use two-module and single-module devices. The latter must have a threshold voltage of 350 V and a negative resistance of 55 Ohms.

For three phases, only a knife switch with a lock is suitable.

Connection of the generator to the cross over switch

To organize the coupling, you will need two modular contacts or an electrical transfer to 7 contacts. A pair of them should be normally closed, and a pair should be normally open. Connection is carried out as follows:

- It is required to enter the extreme contact of the switch to enter the line and cable of the station.

- Middle contact is brought to the consumer.

- The switch is put in its original position - connection to the main network.

- During the switching process, power is supplied from the generator.

- The switch is installed in the control panel.

- To warm up the system and supply power after activating the generator, a time relay is set.

- The backup contactor is powered through the main input communicator by means of a normally closed contact.

Switching processes are implemented by the user. He puts the switch in neutral in the event of a voltage drop.When it is resumed, the first contact is activated, opening the power supply circuit of the second input.

Self assembly cross over switch for generator

Making a knife switch do it yourself step by step:

- Selection of machines according to the number of switching circuits. Two two-pole or 4 single-pole models are placed on a two-phase one.

- Installation of machines in the shield. One is placed in a standard position, the second is turned over.

- Switching nodes with wires.

- Installing a steel lock in the pusher (there are gaps in the machine for it). The bar will allow you to switch all the machines at once.

- Checking the quality of the system - a click should be heard.

A three-position switch cannot be manufactured independently - only a two-position device is obtained.

Practical recommendations for use

Using the switch requires the following rules to be followed:

Using the switch requires the following rules to be followed:

- The device is operated at a temperature from -40 to +50 degrees.

- The reversing switch is placed only in the panel with the mounting plate.

- Manually allowed to activate the circuit breakers with arcing and breaking contacts.

- The burned contact knife is cleaned with a file or glass paper.

- To prevent the legs from skewing, tighten the mounting bolts tightly.

- All active parts of the device are isolated.

- For manual phase transfer, a two-way transfer switch is suitable.

- Select the switch according to the power of the transmitted current.

If there is no voltage in the main network, first the generator starts, and then the switch is put into operation.

Flip switches are suitable for installation in multi-apartment buildings, in production with backup generators. The devices simplify the maintenance of power supplies, control power lines and protect equipment connected to it.