When installing power distribution circuits and complex electronic devices, it is impossible to do without special connecting devices. An electric block is one of the structural elements that are widely used in the arrangement of mounting joints. This product is available in a wide variety of designs, each of which will need to be examined in more detail.

The principle of operation of electric blocks and their types

The basis of the work of electrical connection blocks is the principle of creating a reliable contact obtained by clamping mechanisms of various types. When arranging it, two switched conductors are inserted into the contact holes on both sides, and then clamped into them.

The possibility of arranging the contact without direct contact allows the use of these products for connecting busbars made of dissimilar metals.

The wide selection of contact connectors offered by the domestic market is explained by the variety of their designs, which differ in the following ways:

- the material of which the housing is made;

- the method used to create reliable contact;

- location of terminal mounts.

Body material

Pads for wires differ in the material used for their manufacture. There are ceramic or plastic. In the second case, polypropylene, polyamide, ebonite and carbolite are used as the body material. Ceramics are mainly used for high-temperature operation of switched circuits and equipment (in electric heaters, for example).

Plastic polypropylene is suitable for situations where it is necessary to withstand the loads associated with increased deformations. A typical example of its application is the connection of the connecting circuits of lighting equipment. Carbolite and ebonite products are resistant to vibration, and polyvinyl chloride is traditionally used to equip low-current compounds.

Conductor mounting method

In accordance with the method of mounting the conductors and the mechanism for their fixation, the following types of terminal blocks are distinguished:

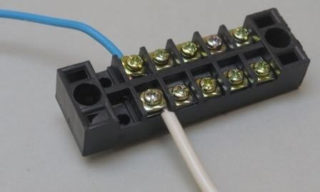

- barrier or building connectors (they are most often called screw);

- clamp type clamps, including self-clamping variety;

- linear type pads, consisting of several terminals located in one row;

- knife terminal blocks.

Connecting pads for wiring with screws guarantee high-quality contact when currents flow in load chains that do not exceed the calculated values. With their help, when installing the power supply, they connect sockets, and also connect the conductors during their installation in niches or cable channels. The reliability of the resulting contact in this case is ensured by special screw clamps. Connectors of this type are not recommended for use with aluminum wires.

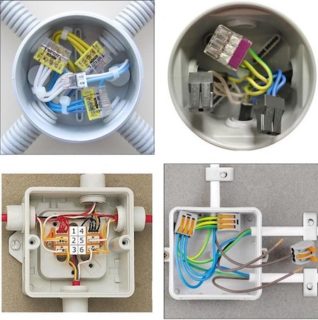

Clamping (or self-clamping) clamps are equipped with elastic spring terminals. To fix the wiring, it is enough to strip its end, and then push it into the block until it stops. To remove the inserted core, simply pull the lever on the terminal to the side. More advanced models have an automatic clamp function.The case of such clamps is made on the basis of polymers, and two brass plates are used as contacts in them.

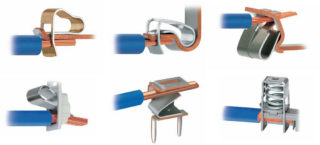

Such pads are convenient to use as a transition element in small junction boxes, where it is sometimes very difficult to establish a reliable connection. To make the connection, the conductor is simply inserted into the terminal until it stops, where it is independently fixed by a spring clip. Knife connectors are traditionally used in the arrangement of grounding and grounding. If there is insulation on the connected wires, it is not necessary to specifically strip it, since it is automatically cleaned during compression.

Pin layout

According to the location of the connecting contacts, the known switch blocks are divided into linear (in the form of a series of terminals) and pass-through. The first are intended for connecting the same type of conductors (earth tires, for example), combined on one completely metal ruler. Feed-through products are in demand when organizing a linear connection of wires and, if necessary, splicing conductors of dissimilar metals (copper and aluminum, for example).

In another variety of such connectors, the terminals are separated by dielectric plastic partitions. If necessary, the desired number of contacts is cut off from such a blank with a knife.

Another type of clamp, called a barrier, looks like a bushing terminal block, but the dividing wall is more thorough. The dielectric fence extends far beyond the contact plane, reliably protecting it from contact with metal objects (screwdriver, for example).

Pad requirements

Connection blocks of any type usually meet the following requirements:

- the material is resistant to high temperatures, avoiding direct combustion;

- with strong heating, deformation of the case is eliminated, the protective shell is made only of non-combustible materials;

- mounted conductors are fixed in the terminals very reliably and inserted into them without much effort;

- contact plates are arranged in such a way as to prevent corrosion when using dissimilar conductors.

In addition, in the technical conditions it is separately indicated that the terminal block must be marked with an indication of the diameter of the cores and the value of the permissible voltage. According to their moisture-proof indicators, they must correspond to the conditions in which they are supposed to be used.

Rules for choosing terminal blocks

Many users often encounter difficulties in choosing connectors for connecting wiring. Before buying switching products, you first need to carefully examine the wire with which you have to work, and first of all determine its cross-section.

Further, it is recommended to pay attention to the following points:

- the quality of the case material, guaranteeing reliable insulation of the terminal;

- When evaluating screw clamps and connector brackets, steel is preferred;

- if possible, the terminals are selected in a compact design, which will allow them to be placed in confined spaces.

Another requirement for connectors is the convenience of their installation and subsequent maintenance.

It is desirable that the surface allows the possibility of additional marking. The inner part of individual samples is filled with a special gel based on rubber, which prevents oxidation of the contacts and increases their reliability.

Mounting Features

The articulation of wires and cables by means of terminal blocks does not require special skill and special skills from the performer.To carry out such an operation, the distribution wiring block itself and two connected ends of the conductors will be required. To form a reliable contact, you should correctly select it according to the size of the nest, which is optimally suitable for the cross section of bare wires. After that, the ends of the wires are inserted into it, which are then fixed with screws. But even earlier, insulation is removed from them at a distance of about 5-7 mm.

Pads from several sections are usually cut into the desired number of segments. When working with soft aluminum conductors (when it is impossible to do without them), they should be clamped with screws with extreme caution, excluding the possibility of punching and metal breakage.

Positive and negative sides

The contact block for electrical wiring has gained wide popularity in electrical engineering due to the following advantages:

- Ease of combining two or more conductors of dissimilar metals with different cross-sections of conductors. No special tool required.

- The ability to save the condition of the wires in a convenient form for re-installation.

- Safety of the resulting compound due to the high quality of the insulating body material.

- Reliability of the formed contacts.

- Resistance of terminals to mechanical and temperature influences, as well as to dangerous tensile and vibration.

- The small size of the products, allowing them to be freely placed in the junction box and the switch housing.

A significant drawback of these devices is the relatively high price (10-12 rubles apiece). With significant volumes of electrical operations, this indicator is sensitive to the budget.

Over time, the cost of connectors will decrease markedly. This is explained by the rapid development of modern technologies and competition in the market of relevant materials. All this even more attracts users to easy-to-use and reliable terminal products.