When performing repairs in the bathroom, the kitchen often has to increase the number of power points. It is important to install the socket on the tile without damaging the lining, so you need to cut the tile on the floor before it is attached to the wall.

The nuances of working with tiles

Facing tile - the material is extremely fragile. Therefore, if the cutting tool / nozzle is incorrectly selected, the square can simply crack. You will have to use new tiles to get the desired result. To avoid this, you should adhere to the recommendations of professionals:

- The holes in the tile for the outlet are drilled only at right angles. Any deviations redistribute the load of the cutting element on the tile and the material cracks.

- The tool works at low speeds: 300-500 rpm. Maximum - 800 rpm.

- It is forbidden to put excessive pressure on the facing material when cutting. This weakens the strength of the tile, which also leads to its splits.

- It is advisable to cut the tiles on the floor, on a special substrate made of wood or chipboard.

- Before drilling, it is better to soak the tiles for an hour in water. This will enhance the strength of the cutting material.

- Before performing work on the surface of the tile, precise marking is applied with a marker.

- It is advisable to glue the intended place of cut with masking tape or any adhesive tape so that the tool does not slip off the smooth surface of the tile.

It is advisable to work with goggles so that small fragments do not damage the eyes.

Necessary tools

In order to mount further undergrowths in the tile, you should prepare a tool for cutting it:

- hammer drill or drill;

- grinder (grinder);

- nibblers (popularly referred to as the "ballerina");

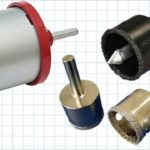

- diamond-coated crown or with victorious teeth;

- nippers, pliers;

- a drill with a greater hardness than that of a tile;

- grinding sand;

- jigsaw.

- Hammer drill

- Jigsaw

- Random orbit sander

- Pliers, pliers

- Nibblers

- Ceramic crowns

- Tile drill bits

- Sandpaper

It is not necessary to buy an expensive tool for one-time work. It can be rented in specialized stores.

Methods for cutting holes in a tile

Before making a hole in the tile for the outlet, it is important to understand that the method is selected depending on the availability of a special tool and certain skills. The principles of operation for each type of equipment are quite simple.

Crown cutting

The principle of operation looks like this:

- Tiles are laid face up on a special wooden flooring. Tile clamped in a vice.

- Accurate markings (circle) are applied to the surface of the cladding. In its center put a point at which the nozzle axis will abut.

- They put a circle of crowns to the marking and at low speeds start work.

The hole must be made in one approach, without changing the angle of inclination of the crown.

Nibblers (ballerina)

Installing outlets on a tile can be done in this way. The ballerina is a nozzle according to the type of school compass on an electric drill. The work is performed in this way:

- Tiles are laid on the substrate "face down" and clamped in a vice.

- The tiles are marked.

- Nibblers are attached to the electric drill chuck.

- Put the tip of the centering drill at the intended point, push the cutting element to the desired distance, fix it and begin cutting. You need to work with the tool at low speeds.

- The edges of the finished hole should be cleaned and trimmed with a sandpaper or emery cloth.

To prevent the electric drill from breaking off during the entire operation, before starting work, you need to make a central hole in the intended circle with a drill with a drill. The tip of the ballerina nozzle is inserted into it.

Tungsten string

This method of processing tiles refers to manual. The risk of damaging tiles is greatly reduced. A tungsten string is inserted into a hand saw as a cutting tool, having previously passed it through a hole that is made on the line of the intended circle. Then the tile is kept on weight, pressing with one hand to the opera, and make a cut.

The thread during operation must be moved translationally-rotationally. The formation time of one nest for a sphincter using a tungsten string is about 30 minutes. The edges of the resulting circumference contribute to the fact that the undersocket is established without problems.

Pobeditovye or diamond drills

With their help, it is possible to gently overcome the technical strength of the tile. The work algorithm is as follows:

- The drill bit with a diameter of 6-8 mm is attached to an electric drill.

- The tile is laid on the substrate and marked on it (a circle equal to the diameter of the cup holder) before cutting a hole for the socket in the tile.

- Using the nozzle on the intended line, you need to drill holes in increments of 0.5-0.8 cm.

- All jumpers are then removed with pliers or special nippers ("parrots").

- The edges of the holes are cleaned with sandpaper.

When working with wire cutters and sandpaper, it is advisable to use protective gloves to avoid cuts. In well-crafted edges, the sockets are easy to install.

Bulgarian

You can work with this tool if you make a hole in two adjacent tiles - cut semicircles along their edges. The work is performed as follows:

- Apply the necessary semicircular marking on both parts of the tile.

- A diamond disk is attached to the grinder.

- The tile is laid on the base surface so that it is in place of the cut on weight.

- The tile is clamped with one hand, pressing it firmly to the substrate.

- With the other hand, make straight cuts from the edge of the facing material to the edge of the arc with a step of 1 cm - as if they cut a semicircle into longitudinal strips.

- Excess pottery is removed with parrot nippers.

The same actions are performed with the second square / rectangle of the cladding. With such a hole for the socket, it will be easy to install a socket.

Jigsaw

This tool works on the principle of a hand saw with a tungsten thread. The only difference is that the translational movements of the cutting element (diamond wire) depend on the electric component of the jigsaw. Move the device along the intended marking line. This tile cutting tool is ideal if the master’s arsenal does not have more modern equipment.

Tile holes

It is better to use a special diamond-coated crown. Before performing work, it is advisable to prepare a special wooden template (jig) with holes of the desired diameter. You can also just select ceramics a little in the center of the outlined circle and make a hole so that the central axis does not slip off the smooth lining.

Work with the conductor is performed as follows:

- The template is applied to the wall in the intended place and begin cutting at low speeds.

- It is advisable to immediately remove ceramic dust.

- Having reached the base of the wall (concrete, brick, foam blocks), the crown with a diamond edge is changed to a more suitable one and continue to work until a nest of the required depth is obtained.

If they work at a central point, a piece of masking tape can be additionally glued to its place. Then the tool is pressed firmly against the wall and the cutting is started, after putting the central axis into the socket. It is important to hold the hammer at an angle of 90 degrees relative to the plane of the cladding. Further, upon reaching the main wall, the crown is also changed to the element “for concrete”, “for gas block”, etc.

When working on an already laid cladding, it is undesirable to make holes along the edges of the tile, at the junction of two or four tile blocks. This often leads to splits, cracks, damage to the material.

Before you make a hole in the tile for the outlet, be sure to prepare protective gloves and glasses. Pottery fragments are injurious. Even if a simple tile cutter or glass cutter is used.

When marking on the dark lining of the marker or pencil on it will not be visible. You can fix this by pasting a piece of masking tape on top. Already on it put the future circle.