An electric generator is a device designed to produce electricity used for specific purposes. A home-made device is capable of performing the function of a source only if certain conditions are met. It is unlikely to be able to assemble it completely from scratch at home. The only way to make an electric generator with your own hands is to use other mechanisms working on the same principle for these purposes. The old engine from a walk-behind tractor or a wind turbine is most suitable. Assembly work will require a lot of effort and money, as well as the presence of certain experience. If there is no complete confidence in luck, it is best to purchase an expensive, but effective branded product.

Device and principle of operation

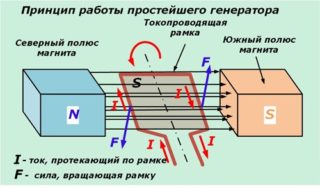

Before you make an electric generator with your own hands in purely home conditions, you will need to familiarize yourself with its design and understand how it works. The basis of such a device is a multi-section winding located on a fixed stator. A movable anchor (rotor) is placed inside, in the construction of which a permanent magnet is provided. This part of the generator is connected by means of a special drive mechanism to a propulsion unit driven by rotation from a windmill or gasoline engine. Alternative energy sources (water or heat generated during the combustion of firewood, for example) can be used as a drive.

- when the rotor rotates, its magnetic lines cross the e / m field of the stator coils;

- due to this, according to the law of Faraday’s induction, an emf of the corresponding magnitude is induced in them;

- a load is connected to the stator coils, the alternating current in which varies in a sinusoid.

Depending on the number of stator windings and the switching circuit, a single-phase 220 Volt or a three-phase (380 Volt) home-made generator can be obtained.

This principle of operation applies to all samples of electrical machines without exception (regardless of the type of drive).

An efficiently working electric current generator, made of auxiliary parts with its own hands, is able to solve a number of domestic problems. Home-made products are traditionally used to generate enough electricity to power a home electrical network. In addition, not very powerful welding equipment or a water pump for irrigating beds in the country can work from the unit. A product made in the form of a wind generator can be operated in the country and on a camping trip.

DIY generator assembly

DIY assembly instructions for current generators involves performing work in several stages. They begin with the preparatory stage, in which it is necessary to stock up on the initial blanks and the required material.

Preparatory stage

To build, you will need:

- An old electric motor from a walk-behind tractor or a wind turbine with a working stator winding. Engine options from an old washing machine or water pump are also popular.

- To equalize the output current, it is desirable to make a rectifier (converter) in advance.

- To facilitate the launch of a future device and the self-excitation of its 220 Volt windings, a high-voltage (at least 400-500 Volt) capacitor with a capacity of 3-7 microfarads is required. Its exact value is selected depending on the planned generator power.

For assembly, you will need long pieces of wire in reliable insulation, an adhesive protective tape and an installation tool (side cutters, pliers and a set of screwdrivers).You should also stock up on a powerful soldering iron, necessary to restore contacts in the broken windings of the old engine.

You should worry in advance about the grounding of the case of a future product that generates voltage dangerous to humans.

Upon completion of the preparation, they proceed to the assembly, the order of which depends on the selected initial sample.

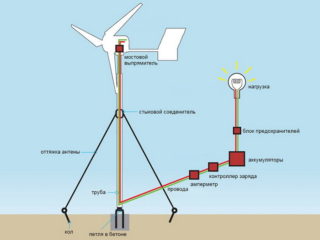

Windmill - the easiest option

The easiest way to perform is to manufacture a wind generator assembled from improvised parts and finished modules. From it very simple electrical loads can operate, the power of which does not exceed 100 watts (a bulb, for example). To make it, you will need:

- (he will work as a generator).

- The carriage and the main sprocket from an adult bike.

- Roller chain from an old motorcycle.

- Bicycle frame.

With a good master, all these improvised workpieces are likely to be found in the garage, of which an electric generator is assembled easily with their own hands.

To familiarize yourself with this procedure, it is advisable to watch a video that details the procedure for making a wind turbine.

An asterisk is installed on the shaft of such an electric motor, which is driven by a roller chain from self-made wind blades mounted on a bicycle frame. With their help, the translational movement of the wind is converted into torque. This design is capable of generating current in a load of up to 6 amperes at a voltage of 14 volts.

Power plant based on a generator from a walk-behind tractor

A more complicated version involves the use of an old walk-behind tractor used as a drive. The function of the generator in this system is performed by an induction motor with a speed of up to 1600 rpm and an effective power of up to 15 kW. In the process of assembly, its drive mechanism is connected via pulleys and a belt to the axis of the walk-behind tractor. The diameter of the pulleys is selected so that the speed of the electric motor converted to the generator is 15% higher than the nameplate value.

Advantages and disadvantages

The advantages of a hand-assembled product include:

- The ability to not depend on interruptions in the operation of power substations, receiving the necessary minimum electricity on their own.

- The self-made generator is tuned to operating parameters that correspond to specific user requests.

- Making it instead of the purchased product will save significant amounts (especially in the situation with 380 Volt asynchronous machines).

A disadvantage of self-manufacturing is considered possible difficulties with the assembly of a particular type of product and the need to spend money on energy (fuel, for example).

Operation tips

Before you make a household electricity generator, you need to familiarize yourself with the rules of its operation. Their essence is as follows:

- Before starting the device, all loads are disconnected so that it runs idle.

- The presence of oil in the working compartment of the generator is checked - its level should be higher than the set mark;

- The device remains on for about 5 minutes, after which it is allowed to connect the load.

In accordance with the rules of operation and maintenance of such generators, the most suitable mode of operation is the use of its power at 70% of the limit value. Subject to this requirement, the equipment will not overheat and will easily cope with the design load.