The supply of electricity to the house underground is a labor-intensive process, but it is quite do-it-yourself. The issue is especially relevant for the electrification of private houses, summer cottages and garden plots. Installation of electrical equipment is carried out in accordance with the standards of GOST and PUE.

Benefits and Vulnerabilities of Underground Electrification

Putting the power cable into the house underground instead of overhead lines has several advantages:

- does not spoil the architecture and design of the site;

- does not experience atmospheric effects;

- high fire safety.

In addition, the eyeliner made in this way is protected from theft and vandalism. What is especially important if the building remains unattended for a long time.

The underground cable routing has some negative aspects:

- may be subjected to mechanical stress in the process of expansion and subsidence of the soil;

- the influence of groundwater, soil freezing, root pressure of large trees;

- insects and rodents can damage the wiring;

- it is susceptible to aging and corrosion.

The durability of the electrical wiring depends on the composition of the soil and its saturation with water, thermal fluctuations and vibration processes.

Obtaining permission for underground input

First you need to complete the project. Its development should be carried out by a specialist. Technical documentation, plans and drawings must comply with all rules and regulations. The designer determines the brand of cable, calculates the cross section of the conductive wires.

To receive the project, it is necessary to fulfill a number of technical conditions. To connect the house to a common power line, you will need an appropriate permit. For example, an agreement for earthworks is drawn up by a service responsible for facilities and communications.

Then a trace of the land is carried out. If there are any communications in the immediate vicinity of the cable being laid, it is necessary to invite their representative to coordinate the position of the trench and control the work performed.

Cable Product Compliance

To bring electricity to the house, use products designed for laying in the ground. Since the electric cable will be under the pressure of the mass of soil, products are used in a special braid, armor. These are such brands as, WB bShVV and WB bShVng. The first letter in the marking indicates the presence of copper conductive cores. Reservations are made with corrugated steel tape. It is wound in the form of a spiral, along the inner layer of insulation.

Products are resistant to mechanical damage. Installation can be done without piping. However, in order to avoid damage during operation, it is recommended to use a pipe. If the earth has increased chemical activity - salt marshes, swamps, slag, construction debris - use a cable with lead armor or an aluminum sheath.

Given the complexity of installation work, it is better to immediately choose a high-quality cable, even if it costs more.

Input using unarmored cable and HDPE pipe

If you need to supply electricity underground in the country, you can use an ordinary wire in a PVC sheath. For laying in the ground, it is better to choose tight and sufficiently strong brands of cable products - NYM, VVG or SIP. They can be used, for example, to conduct lighting in a country cellar.However, products with active external exposure quickly fail.

To extend the service life, pipes made of low pressure polyethylene (HDPE) are used as protection. They reliably protect against stray currents, mechanical damage and the influence of aggressive soil. Corrugated products can be used for this purpose. They have increased elasticity and strength, easily restore their linear dimensions, easy to install. With frequent repairs, they can be reused. Some models are equipped with a probe, which simplifies the pulling of the cable inside the corrugation.

Cable Management

The norm of the depth of the trench is 90 cm, the thickness of the sand cushion is up to 20 cm. The cable is laid without tension, wavy, always below the freezing point of the soil. Then it is covered with a layer of sand of 30 cm and soil, after having laid down the warning tape.

If the soil is subject to shear, not dense, filled with groundwater, additional protection is established. Make a tray of concrete blocks or moisture-resistant bricks. The cable is laid in a tray, the top is covered with a concrete slab. A reinforced concrete monolithic channel is made on creeping soil and covered with reinforced slabs.

Cable output

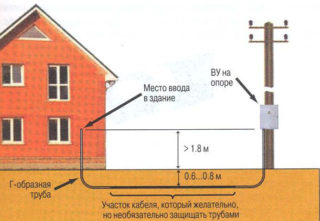

At the exit from the ground, before connecting to the pole, a 2 meter cable section should be closed by a curved metal pipe. The bending radius is at least 20 diameters of the cable sheath.

When laying the cable in the ground at the cottage to the house, you should enter it through the foundation, for this you need to provide a mortgage. This is a piece of pipe extending 10-15 centimeters from the foundation on both sides. Its cross section should be 4 times larger than the wire being laid. Through it, it is easy to enter the cable into the room. For subsequent sealing use a mounting foam or rags soaked in cement milk.

In another method, the cable in a metal pipe is lifted along the house. This is usually the place where the opening cabinet hangs. A mortgage is made in the wall, adhering to the same parameters, and a wire is brought into the house. This method is used if the foundation is made of a monolithic slab and you do not want to break it.

You can make the laying of the electric cable underground by the puncture method. This method is used if wiring must be laid under a section of road or garden path. The essence of the method is the creation of a channel by pressing a metal pipe with a tip into the ground. In this case, the soil around the device is compacted.

Two pits are made on either side of the obstacle, one starting, the other receiving. On the pipe using a grinder cut the teeth in the form of a crown. The diameter should correspond to the size of the wire, but not less than 20 mm.

Work is best done together. The end of the pipe with a crown is installed in the starting hole. On the other end hit with a sledgehammer with great force. After passing a 50 cm path, the inside of the pipe is washed from the ground with water under pressure.

If the length of the receiving pit is not enough, an additional segment is welded. When the crown teeth appear on the other hand, the process is over. The protruding ends are cut off from both sides, and a cable is inserted into the middle part. In this case, the pipe remaining in the ground is a protection.

Warnings

The underground cable for electricity in a private house should only be armored.

The metal pipe for wiring should not be continuous, since when it is filled with groundwater, ice formed in severe frost will damage the cable.

Wiring necessarily needs grounding. For this, a separate insulated wire is soldered to the armor. The second end is connected to the ground on the shield or zero terminal. In case of emergency, the machine will turn off the power.

Choosing the right cable, observing all the requirements when installing it, is the basis for a long and safe operation of the electric main.