380V power sockets are widely used in industry and construction. The design withstands both mechanical and electrical loads. Convenient fasteners prevent short circuits and equipment failure. Unique features, easy connection and safe operation are the main advantages of this product. The main thing is to correctly connect a power outlet with a capacity of 380 volts.

Features of the 380V socket

Power cable connectors are designed for harsh technical conditions. An industrial plug and a reinforced 380v power socket are protected by a robust housing that can withstand small bumps. Simplicity of connection, strong plastic and high throughput allow using the connecting structure in the open air, in industrial plants or during construction work. The product has high security requirements.

The contacts have a large contact area, which reduces the load and eliminates possible overheating. Each cable clamp is fastened with a screw connection that holds the wire in its seat. The copper construction is protected against corrosion and also resistant to oxide film growth.

The clamp holds the cable securely, preventing breakage. Special grooves provide a strong connection and eliminate backlash. Contacts have different diameters and are located at their own angle. The connection provides protection against unbalanced connections, which prevents short circuits.

With high voltage, the risk of arcing increases. Each socket 380 has mechanical or automatic protection. The device is able to stop the power supply before being removed. The solution reduces the risk of equipment damage or skin burns.

Plastic is resistant to overheating, is non-combustible and is able to withstand direct sunlight. Protection against dust and moisture is provided, which will preserve the quality of parts and make work safe.

A 380 volt electrical outlet is manufactured in accordance with IP 44 or IP67.

Types of Outlets

Power connections differ in shape, mounting method and number of contacts. A power outlet can have 3 to 5 connections. To understand the difference, it is important to study the principle of work. In the CIS countries, a three-phase network with a voltage of 380V is used. The standard apartment uses 220V. This indicator can be obtained by connecting one of the three phases with a neutral wire. To connect an industrial outlet to 380 volts, it is enough to combine the two phases and the neutral wire. A similar connection principle has a conventional electric stove.

There are several standards for power connectors:

- 2P + PE - two phases and one grounded contact are used;

- 3P + PE - 3 power cables and one grounded;

- 3P + PE + N - 3 phases, one earth and zero;

- 3P + N - three power contacts and one zero.

- Socket 380V 2P + PE

- Socket 380 3P + PE

- Socket 3P + PE + N

- Plug 380 3P + N

Switching connections differ not only in the number of contacts, but also in the structure of the housing. There are cable structures that serve to connect portable devices. The flange switches are made with a mount that can be built into the wall directly or at an angle. The last type is overhead sockets. Some cases are equipped with an additional protective cap.

Marking

The letter P represents the power or phase conductor, N the neutral, and the PE designation indicates the grounding cable. The wires are also color-coded.Electrical installation rules require you to indicate the phase in burgundy, red or brown, zero - in blue or blue. The earth is painted in two colors - yellow and green.

The letter P represents the power or phase conductor, N the neutral, and the PE designation indicates the grounding cable. The wires are also color-coded.Electrical installation rules require you to indicate the phase in burgundy, red or brown, zero - in blue or blue. The earth is painted in two colors - yellow and green.

In addition to the voltage, the maximum permissible current strength is indicated on the case. An industrial 380v socket is able to withstand 16A, which is acceptable for a conventional network. For more powerful ones, connections are used at 32, 63 and 125 amperes. To avoid overheating and ignition, it is important to check the current strength of the mains in advance.

Also, marking may indicate the degree of protection. IP44 indicates that the receptacle isolates conductive pads from splashing water and dust particles. Often, such cases are equipped with overhead protection.

IP64 marking assumes a completely sealed enclosure. Maximum protection allows connections in rooms or in open spaces with high humidity.

Connection Methods

High voltage is life threatening, therefore, TB and connection rules should not be neglected.

The foundation of any connection is cable. It is important to choose the right section, suitable in size and able to withstand the potential load. According to GOST, for a socket with a voltage of 380 V and a current of 16 A, a wire with a cross section of 1.5 to 4 mm is enough. The plug cable must be at least 1.5 and not more than 2.5 mm. The thickness of the ground wire should be 6 mm.

When mounting the switching elements, it is important to use the rule: the supply cable is a socket, the receiving cable is a plug. When stripping a wire, breakage or entanglement of the core must not be allowed. The more uniform the contact part of the cable, the better the transmission and less overheating.

Four wire networks

Installation of wires begins with the disassembly of the housing. Commutateornaya socket on the 380 volt It has 4 pins, three of which are phase. Near the contacts, you need to find the designation L1 L2 L3 and in random order connect three phase wires to them. Next, you need to find the neutral wire and clamp it on the terminal, signed with the letter N.

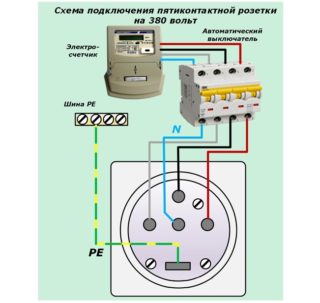

Five wire networks

When connecting a five-pin connector, a circuit similar to the previous one is used. The designation near the pads is the same: L1 L2 L3 - phase, N - zero and PE - ground wire. The presence of land requires an additional element of the circuit - an RCD machine. This bundle will prevent electric shock if the case or mounting rail is live.

When connecting a five-pin connector, a circuit similar to the previous one is used. The designation near the pads is the same: L1 L2 L3 - phase, N - zero and PE - ground wire. The presence of land requires an additional element of the circuit - an RCD machine. This bundle will prevent electric shock if the case or mounting rail is live.

Connecting a three-phase outlet

Connection can occur with or without RCD. It all depends on the availability of a protective grounding cable. The connection is symmetrical, so the order of connecting the power cables is arbitrary. At the end of installation work, check the connection and correct errors.

Checking Outlets

Before operation, it is important to make a check, which consists of four main points:

Before operation, it is important to make a check, which consists of four main points:

- Visual inspection for possible physical defects in the housing.

- In the presence of a megohmmeter, the strength of the insulation coating is checked. During diagnosis, the 380 volt outlet must be de-energized.

- Using the device, a short circuit is triggered to check the connection.

- Measurement of line and phase voltage at idle.

During the test, the operating voltage between the phases should be no more than 380V and 220V on one core. In the end, you should once again check the correctness and quality of the connection. A loose contact will overheat and fail, damaging the housing.

When the circuit is opened, an arc can occur that creates a danger to life and a risk of breakage. To avoid this phenomenon, always disconnect the current supply before dismantling. In more expensive versions there is a machine.

During operation, the wires heat up and expand. As a result, screw connections become loose, resulting in poor contact. Every year it is necessary to carry out the pulling of all wires.