Corrugation for wires in accordance with the rules for installing electrical equipment is installed when laying low-voltage networks and wiring. This is due to safety measures, since the corrugated pipe for the cable is an excellent dielectric and protects the wires from mechanical and thermal stress. Thus, corrugation for wiring is an additional insulation.

The purpose of the corrugation in the electrical wiring

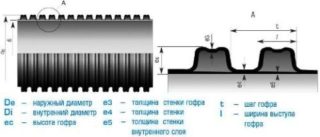

Corrugation can be called one of the most useful and sought after inventions. Its characteristic feature is a variable cross section. The pipe has short sections with a small diameter and thin walls, as well as sections with a large diameter and thick walls. The latter add stiffness to the pipe, its resistance to mechanical stress increases, and the former allow you to take various forms and even stretch within certain limits.

Due to its strength and flexibility, the product has been widely used not only in the installation of electrical wiring, but also in exhaust ducts and ventilation systems, in split systems and air conditioners for condensate drainage, in plumbing for connection to drainage siphons, in the automotive industry. For electric cables, a special wiring corrugation made of PVC is used.

Product design

If the electrical hose is cut along, the profile will have a rectangular shape. The main distinguishing feature of the product is the presence of a broach in the internal cavity (a thin steel wire is a probe designed to tighten the bundles into the pipe). For wires, as a rule, the pipe has a gray color, but foreign corrugations are red and blue.

Corrugations are metal, but more often made of plastic. This is due to a more acceptable cost of material.

The advantages of electric corrugation

Corrugated pipes for electrical wiring are in great demand, and in some cases are required to use due to the following advantageous features:

- Long service life. Subject to installation rules and a careful attitude, the service life exceeds 50 years, all material properties are preserved.

- Light weight, which greatly facilitates the process of transportation and subsequent installation.

- If a rubber gasket is installed at the junction of parts, you should not be afraid of moisture entering the pipe, the material itself is waterproof.

- The material is environmentally friendly, does not decompose over years into individual components, does not harm human health.

- Non-combustible corrugation for wiring has excellent resistance to thermal effects.

- The material of manufacture is not oxidized, is not subject to corrosion.

- High rates of resistance to mechanical stress.

- Does not react chemically with active chemicals.

- Operating temperature ranges from -20 to +60 degrees.

Of the shortcomings, it is worth noting that at temperatures below -20 degrees polyethylene pipes can burst.

Types and types of tubes

Various types of pipes are produced, since they are used for UTP cable, power, television and telephone, as well as for underground, hidden and outdoor wiring. They differ in design, construction and material of manufacture.

In the manufacture of corrugations, the following materials are used:

- Polyamide (PA).The advantage of the material is its highly reliable waterproofing.

- Polyvinyl chloride (PVC) is in demand due to its self-extinguishing.

- Polypropylene (PP) - is used for laying in electrically conductive trenches at the construction stage using monolithic technology.

- Low-pressure polyethylene (HDPE) - this material is the most flexible of all existing analogues.

- High pressure polyethylene (LDPE) - is used to lay hidden wiring in the foam block, concrete, brick and other materials that are not exposed to combustion.

- Polyamide

- PFH

- PND

When laying wiring in the corrugation on a wooden ceiling, reinforced metal heat-resistant materials are used. In other circumstances, it is impractical to mount a metal hose because of the high cost.

There is also a decorative pipe, but it is practically not used for electrical wiring.

For various conditions of use and installation, the following types of corrugated hoses for electrical wiring are made:

- Heavy - this variety has thicker walls, which greatly increases the service life and strength of the product. A pipe is used for installation under a cement-concrete screed.

- Light type used for internal wiring. These hoses are characterized by excellent flexibility, which is achieved due to the small wall thickness. Most often installed under drywall or other skins.

In order to make wires into the corrugation easy, the latter is additionally equipped with steel wire - a probe located inside the cable.

Diameter and packaging

The ratio of the outer and inner diameters of the corrugations for wires of different materials is given in the table.

| Metal corrugations | Fireproof Plastic Corrugations | ||

| Outside Diameter (mm) | Diameter of inner surface (mm) | Outside Diameter (mm) |

Diameter of inner surface (mm)

|

| 9,8 | 5,1 | 16 | 10,7 |

| 11 | 7,7 | 20 | 14,1 |

| 13,5 | 9,7 | 25 | 18,3 |

| 15,6 | 11,7 | 32 | 24,5 |

| 19 | 14,7 | 40 | 31,5 |

| 22 | 18 | 50 | 39,6 |

| 30,3 | 24,5 | ||

| 38 | 31,5 | ||

| 45 | 37,5 | ||

| 58 | 49,5 | ||

| 71,5 | 62,5 | ||

| 87,5 | 78 | ||

A building product is being sold in bays. The length of the light type can vary between 50-100 meters, and the heavy 2 - 25 meters. For ease of transportation at the factory, they are packaged in shrink film made of polyethylene.

Criteria for choosing corrugations for electricians

It is important to decide which corrugation to use for wiring in an apartment or house, since the safety of staying indoors is above all.

It is important to decide which corrugation to use for wiring in an apartment or house, since the safety of staying indoors is above all.

The selection criteria, relying on which, will be able to choose the right product:

- The accompanying document always contains information about the flexibility of the pipe, but despite this, you need to personally verify this.

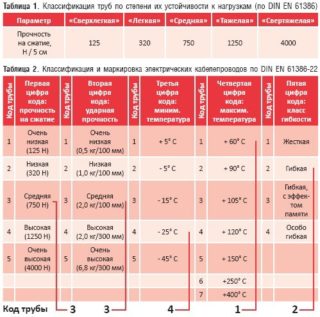

- Modern hoses for electric cables are produced with the calculation of permissible loads in the range of 125 - 4,000 Newtons / cm2.

- Operating temperature ranges from -50 to +420 degrees.

It is important to consider not only static, but also shock effects. In serial corrugated pipes, the maximum threshold is 6.7 kg per 100 mm.sq.

Mounting Features

The installation of corrugated pipes has several stages, the main of which are laying an electric cable and attaching pipes with wiring to surfaces, it is also worth considering the most common difficulties that arise when using products.

Corrugation installation is divided into two types - open and closed. Each has its own characteristics.

- In the first case, for fixing the hose it is required to use special clips made of plastic. They come in different sizes, the choice depends on the diameter of the corrugated pipes used.

- The clips are placed at intervals of 30-40 cm. They are attached to the surfaces using screws or dowels. The choice depends on the material the surface is made of (concrete, brick, wood, etc.).

- In clips, the pipe is fixed securely. To do this, the corrugation is pressed into the clip until a characteristic click appears.With correctly selected sizes, the probability of spontaneous loss of the pipe is excluded.

- With flush mounting, clips can be used, but this is very inconvenient, since they take up a lot of space. An exception is the installation of a corrugated pipe in the screed, on top of which a large layer of mortar will be applied to hide all the bumps.

- For installation in walls, wall plugs, plastic staples, or any home-made options cut from sheet metal are used.

When designing the path where the wiring will be carried out, the following points should be taken into account:

- The length of each individual section should not exceed 25 meters, the permissible number of turns is 4.

- Turns should not be close to each other, the optimal interval is 4-5 meters. If this is not possible, an additional junction box is installed.

- The maximum possible turning radius is 90 degrees, but the smoother the better.

There are no difficulties in installing corrugated pipes with electrical wiring. During the work, it is important to observe personal safety precautions - the power supply is turned off, the voltage is checked.